Products

Metal detector M6-h series

INQUIRYAnritsu - Metal Detector - M6-h with the highest detection sensitivity in the market!

Anritsu metal detectors have one of the highest detection sensitivity in the market, metal detector detection sensitivity for Fe (iron) sphere in diameter of 0.25 mm / SS 304 (stainless steel) sphere in diameter of 0.6mm. Metal detectors can work with packaged and unpackaged products, metal detectors can work with foil type aluminized packaging, and metal detectors can work with liquid products containing water - soups, pickles, and more. Metal detectors can work with frozen, hot products as with many other types of products. Stable, reliable metal determination.

All Anritsu Tunnel metal detectors are with high production standards that provide stable, reliable metal detector performance to detect all types of metals across a wide range of food and non-food processing, regardless of working environment.

Metal detectors are suitable for detecting foreign objects in industries such as food, fisheries, meat, vegetables, pharmaceuticals, cosmetics, textiles, recycling, etc.

Anritsu metal detectors have IP66 protection class and can be washed with a water jet - inside pipe diameter: 12.5 mm.

For a metal detector, the conveyor speed ranges from 5 m / min to 90 m / min - each product registered can work at its own belt speed.

Metal detectors are equipped with USB port, via this USB port the operational history of metal detector can be downloaded.

Anritsu metal detectors have Ethernet interface (10BASE-T, 100BASE-TX).

DESCRIPTION

- Dual-frequncy system

- Detection sensitivity: Fe sphere 0.25 mm dia. / SUS sphere 0.6 mm dia.

- Protection class: IP66 / IP30

Improved Metal Detection Capacity - Anritsu - High Sensitivity Metal Detector - The M6-h will provide the production line with high metal detection sensitivity and equipment stability from environmental factors (vibrations, temperatures, electromagnetic fields, etc.)

To provide the level of detection described in the catalogues, while working with a metal detector on actual product manufacturing lines, is a major challenge for metal detectors. Considering the determination of detection sensitivity can vary depending on the product and environmental conditions, including temperature and humidity, independent determination of detection sensitivity can be a challenge.

The Anritsu M6-h Series Metal Detector is designed to provide your product manufacturing lines with high and unmatched detection sensitivity of all types of metal. The automatic product registration process of metal detector allows you to quickly achieve excellent results.

|

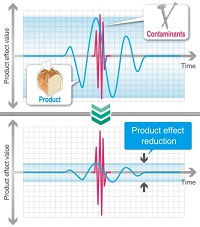

Anritsu M6-h series metal detector with improved digital signal processing Built-in digital signal processing (pending patent) better isolates the effect of your product on the detection sensitivity of a metal detector and reduces the impact of its product on detection sensitivity. Excellent metal detection is made easy.

|

Anritsu M6 series metal detector with improved automatic product registration delivers outstanding performance Improvements in metal detector detection sensitivity and performance were developed internally by ANRITSU, with over 50 years of experience in this industry of quality control equipment production. Has developed an excellent automatic product registration process

|

|

Vibration and electrical noise resistantMetal detectors look for fluctuation within magnetic fields the product passes through the detector head. Since the magnetic fields are affected by external sources such as floor vibration and inverters from nearby machines, a metal detectors must be designed to handle these challenges. With this in mind, Anritsu’s detection heads are designed to provide high sensitivity without sacrificing repeatability and reliability.

|

|

|

The FOCUS functionMetal contaminants come in all shapes and sizes such as wires, shavings and flakes. The FOKUS function delivers enhanced detection of those hard – to – detect real world contaminants.

*Detection enhancement may vary depending on contaminant types. |

|

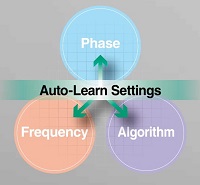

||

High sensitivity detection of both ferrous and non – ferrous metalAnritsu’s patented dual – frequency technology is optimized for both ferrous and non – ferrous metal simultaneously. With the improved auto – learn process, Anritsu systems analyse more than 10.000combinations of frequencies and algorithms to provide the best detection possible.

|

|

|

Conveyor belt removal without toolsFor maintenance - cleaning of metal detector conveyor Anritsu has thought in order the M6-h series metal detector conveyor belt can be easily removed or fitted without the need for tools. This system is designed for water-washable models that allow quick and easy cleaning.

|

||

Full conveyor belt speed controlAnritsu metal detector conveyor belt speed can be adjusted (from 5 to 90 m / min), is stored in product settings. Each registered product can move at its own unique speed.

|

|||

There is no need to adjust the conveyor belt tensionWith the automatic conveyor belt tensioner, you no longer need to tension the conveyor belt. Direction changers are also available for water-washable models.

|

|

||

Metal detector product registration navigation - device instruction manual no longer needed

Automatic product registration process - all displayed on the screen with illustrated pictures and step-by-step instructions that the operator must do to register the product.

Multilingual display and global service network

Various on-screen languages including English, Russian, Spanish, Portuguese, German, French and more.

Anritsu's service network is available in more than 50 countries for fast delivery of replacement parts and service.

|

False product rejection is minimized Anritsu metal detectors have built-in trouble-shooting windows - these show the possible causes of fake product rejection and display on-screen hints to improve device performance.

|

Improved troubleshooting and help windows Anritsu metal detector unique error and alarm codes with descriptions and providing directions to fix errors and reduce service needs. Reduces line downtime.

|

|

|

|

Features and Functions of M6-h series / M5 series

Diagnostic function: Allows the operator to check items that can cause false reject – preventing problems before they occur.

History recording: Complete error and alarm status is recorded and can be checked at a glance.

Quick machine warm – up: Get up and running faster with better system stability.

Increase quality and protect your brand reputation

Smart Guide Function - Ideal for (CCP) HACCP, IFS, BRC, SQF, FSSC 22000

Metal detectors are considered a must-have control point (CCP) in HACCP programs, and they must perform the detection of metal foreign object in your products to make sure the metal detector is working properly. When you turn on this feature - Smart Guide. Smart Guide in metal detector performs performance checks in easy-to-understand format. It can be set so that the metal detector would stop if machine fails during the testing of metal test standard. These steps must be taken when turning the machine on, off, or replacing the product. Everything on the screen is displayed. Also, operator training is minimized.

|

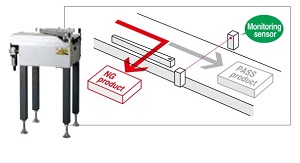

Confirmation of rejection Not only should the product with a metal particle / foreign object be determined, it should be properly removed from the line / discarded. Anritsu rejection confirmation ensures that the rejected product, if not removed from the line and crosses the photo sensor, stops the line. This ensures 100% removal of the negative product from the product line. |

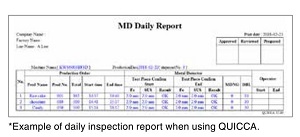

Daily inspection reportSimplified data and long management allows quick response to retailers or customer quality inquires. |

|

|

|

Metal detectors come with multiple user levels Each operator level can be equipped with its own access permissions. This helps to avoid human error and possible operator errors. An additional barcode reader simplifies operator identification. |

Metal detectors are subjected to tests that meet global standards Anritsu metal detector manufacturer carries out rigorous testing to meet national and international standards such as CE marking and FCC. Anritsu metal detectors offer a reliable solution for quality control in the food industry worldwide. |

|

|

HACCP complianceHACCP compliance requires verifying the operation of the inspection equipment in a regular basis. QUICCA automatically records these operation checks and the associated product name, time / data and the operator ID who performed the check. QUICCA helps prevent omissions in data recording and falsification of data, improving consistency of inspection reports. The system provides a report to HACCP requirement, that a product has been inspected with a fully compliant inspection system. You can show your customers that your manufacturing process uses and follows stringent quality control processes and can increase your company’s brand image. (Anritsu is not responsible for the inspection results by this documentation.) |

Complete product traceabilityAdvanced line monitoringOverall quality management and control system, QUICCA, offers real – time product line monitoring and analysis as well as advanced traceability for each product. With centralized information, QUICCA can aid in detection production issues before they become a larger problem. |

|

|

|

M6-h metal detector - available sizes

The conveyor widths are from 210mm to 450mm, the standard conveyor lengths are 800mm, but longer conveyors are available as an option.

Metal detector head throughput heights dimensions are from 45mm to 180mm

Each series features a variety of detection areas to suit a wide range of products. For details of specifications, please submit an online inquiry form.

Video