Products

ALTECH ALcode – Pallet Labelling System

INQUIRYStandalone Multi-Face Robotic Pallet Labeller

ALcode P with Integrated Panel PC Controller

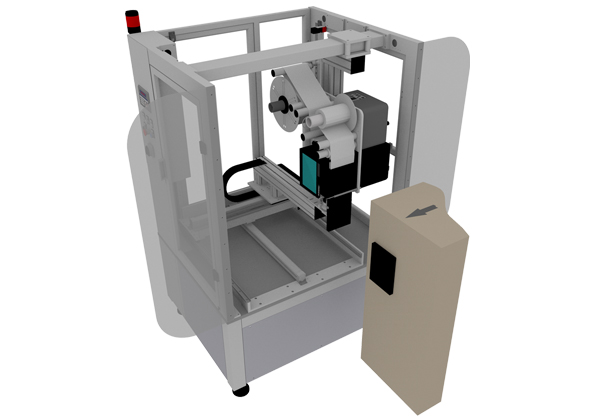

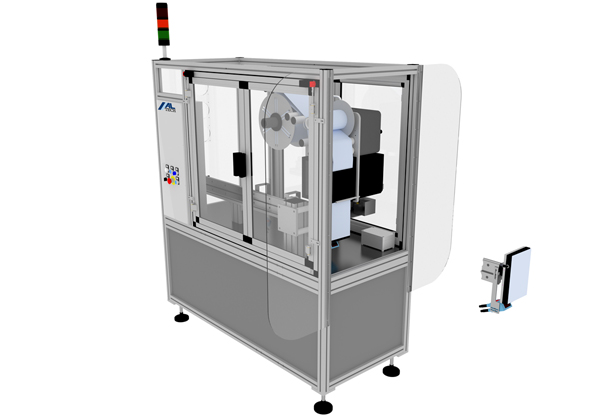

The ALcode P is a high-performance pallet labelling system designed for multi-side label application. It primarily applies A5-size labels to two adjacent faces of a stationary pallet in a single cycle. Custom configurations for additional labelling requirements are available on request.

ALcode P Operation and Design

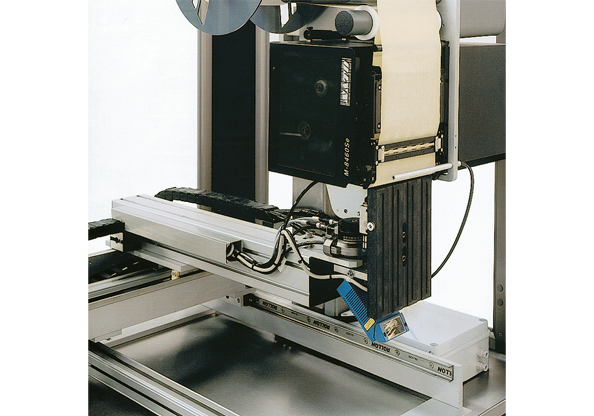

The ALcode P features a highly robust tri-axial linear motion system with roller bearings and a rotating labelling head, enabling rapid and precise label transfer from the printer to the pallet surface—even when handling pallets of varying shapes and dimensions.

By default, labels are applied using a flexible tamp application head equipped with digital pressure sensors. These sensors monitor contact with the pallet and automatically retract the head once the preset pressure is reached, ensuring accurate and consistent label placement.

This universal and adaptable design can be configured with extended axis strokes for non-standard pallet sizes or customized to execute multiple labelling logics, such as applying two labels per pallet face (front and side, or side and rear). It can also apply up to three labels (front, side, and rear) in one or two pallet stops.

The ALcode P integrates advanced thermal print engines from leading manufacturers Sato and Zebra. This guarantees top-tier printing performance, speed, and compatibility with existing labelling or business control software (such as SAP) through multiple interface options, including Ethernet connectivity.

For easy maintenance and minimal downtime, the print engine can be quickly “hot-swapped.”

Standard configurations support label reels up to 300 mm in diameter (on a 76 mm core), with an optional 400 mm unwind unit and high-capacity rewinder available to more than double operating time between media changes.

A wide range of optional enhancements is also available, including customer-specific PLC systems, integrated label management software serving as a middleware link to ERP platforms (e.g., SAP), and customized logic signalling to match specific line requirements.

Key Features

- Fully integrated, unattended pallet labelling system for multiple sides

- Durable all-in-one design with standard protective cabinet

- Optional positive air pressure, heating, and automatic door opening systems for demanding environments

- Integrated label placement verification and barcode reading for quality assurance

- Custom configurations for extended stroke, special label sizes, additional labels, and variable application heights

- Compatible with leading thermal transfer print engines for seamless integration with host systems (e.g., ZPL, SBL, etc.)

- Hot-swappable print engine design for quick maintenance and minimal downtime

Technical Specifications

| Print Type | Thermal Transfer |

|---|---|

| Interfaces | RS232C, Centronics, USB, LAN |

| Max Print Width | 167.5mm |

| Max Media Width (inc liner) |

180mm |

| Resolution | 203dpi (8 dot per inch) 305dpi (12 dot per inch) |

| Print Speed | Up to 400mm/sec |

| Applicator Type | Pneumatic |

| Standard Configurations | Two adjacent sides applicator for pallets Front/side or side/back logic in a single pallet stop Left or right packaging line position, no change parts |

| Special Configurations | Long stroke single side pallet applicator (ALcode L) Front-only pallet labeller Three-sides pallet labeller Multiple labels per pallet face |

| Production Speed | Up to 180 pallets/h depending on label size and configuration |

| Label Roll Diameter | 300 mm (option: 400 mm) |

| Power Supply | 220V, 50 Hz, 800W |

| Pneumatic Supply | 5 bars, 50 litre/min |

ALcode L - Pallet Labeller 500mm Stroke

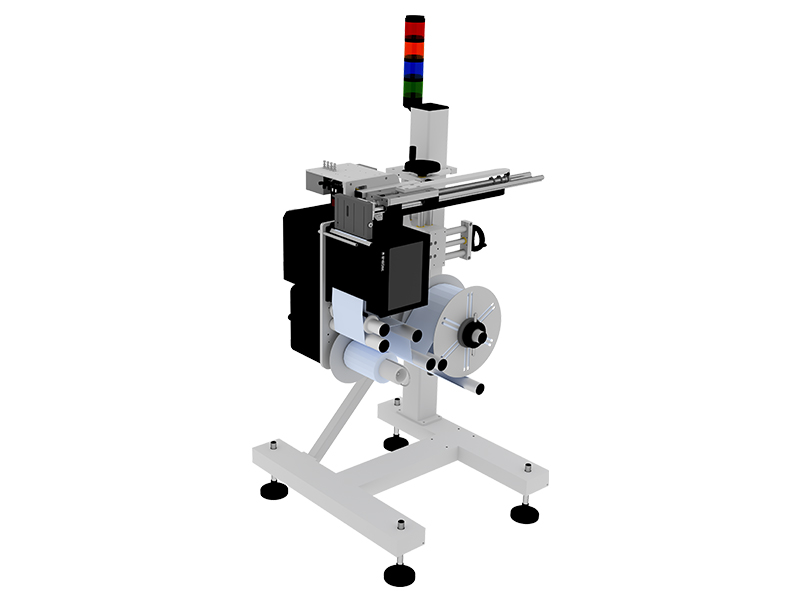

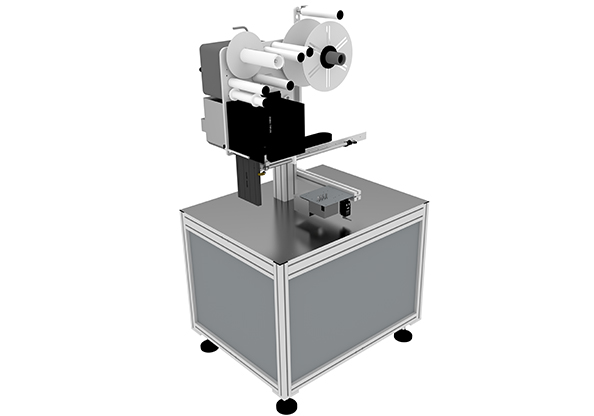

The ALcode L series represents our single-axis linear stroke pallet labelling systems, typically installed alongside pallet conveyor lines or integrated within pallet stretch wrapper cells (rotary turntables). This configuration enables multi-side pallet labelling through controlled pallet rotation.

Each ALcode L unit features a user-friendly 7" colour touchscreen for clear machine status display and easy configuration. The system retains full flexibility with an integrated PLC controller for customized line communication. Label handling is designed for efficiency, supporting either a 300 mm (450 m) or optional 400 mm (900 m) unwind with matching high-capacity rewinder—ensuring extended runtime and simplified media changes through an optimized label path.

Where special applications are required, our engineering team provides tailored solutions, including slide-extraction mechanisms, telescopic strokes, and “on-the-fly” labelling without stopping the pallet. Additional options include variable-height operation for partial pallets and even integration of an industrial stapler for applying labels directly onto wooden pallets.