Products

ALpharma – self-adhesive labelling systems

INQUIRYALpharma – self-adhesive labelling system

Pharmaceutical labelling systems ALpharma self-adhesive labelling system is designed by the ALTech specifically for labelling pharmaceutical products. Based on the broad experience gained in designing innovative labelling systems over the last 30 years, which are exceptionally successfully proven in all market sectors, ALTECH have specially developed the ALpharma labelling system range, whose highly advanced features fully comply with the strict provisions and requirements of the pharmaceutical industry.

This range is designed according to the standards of good engineering practices (GEP), with particular attention to a range of specific needs, for instance:

• Easy cleaning of the machine thanks to its smooth surfaces, with a minimal number of partitions and a high position of the electrical parts and/or their protection against liquid spills.

• Ergonomic mechanical parts, easy format change, repeatable settings.

• High-quality materials, including stainless steel (AISI 304 or 316).

• The integration of label printing devices for the print of essential data (batch codes, due dates), by means of hot foil or thermal transfer printing units.

• The integration of sensors for correct application, overprinting and labelling check

• Integration of an built-in control systems, equipped with Siemens S7-300 PLC, and a touch screen interface which manages all functions of the machine and its checking devices.

• The possibility of certifying the machine as per GAMP (IQ/OQ/PQ) validation process, with the provision of the related documents and the performance of tests (FAT, SAT) according to these procedures.

ALpharma models:

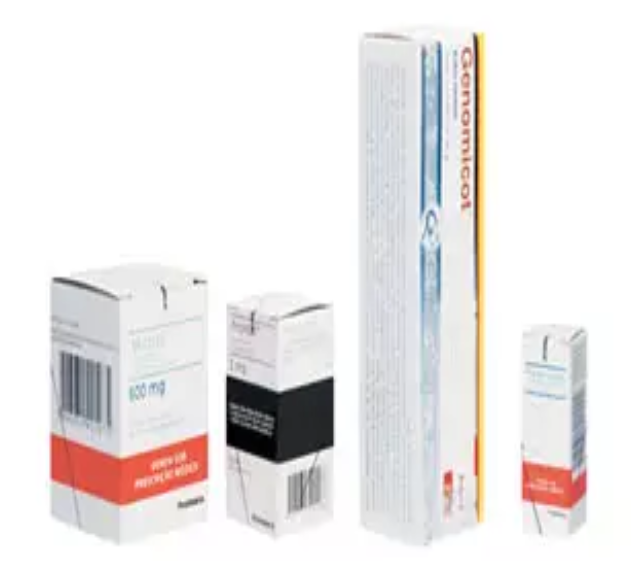

• ALpharma A, for labelling vials and small bottles. The labelling is performed from tray to tray, in a star-wheel. Up to 150 products/min.

• ALpharma B, for labelling cartons, with both barcode labels (tags, vignettes) and tamper-evident (generally transparent) tamper tabs folded along the flaps (up to 200 products/min).

• ALpharma C, for in-line wrap-around labelling of small cylindrical bottles. Up to 250 products/min.

Options:

• Hot or thermal transfer overprinting

• Checking device for near end of reel and rewinder full

• Checking device for near products

• Checking device for bar codes

• Checking device for performed and/or correct overprinting by means of mark readers or a video-camera

• Checking device for performed labelling by means of luminescence sensors or a video-camera

• Ejection of non-compliant products with checking device for performed ejection and rejects box full

• Management of formats and management of alarms and rejects log.

ALpharma A - system for labelling vials and small bottles

Designed for labelling vials and small bottles, the labelling is performed from tray to tray, in a star-wheel. Speed: up to 150 products/min.

Available options:

• Overprinting with hot-foil or thermal-transfer printing

• Near end-of-reel and rewinder-full monitoring

• Near product monitoring

• Barcode checking

• Sensors to check for correct/performed overprinting, with print mark reading or camera

• Sensors to check that labelling has been correctly performed, with luminescence sensors or camera

• Expulsion of rejected products with check that expulsion has occurred and rejects box full monitoring

• Management of formats, alarms history and rejects.

Technical specifications ALpharma A

Power supply – 400 V 50 Hz three-phase | Power Consumption – 1 Kw | Performances up to 150 pcs/min

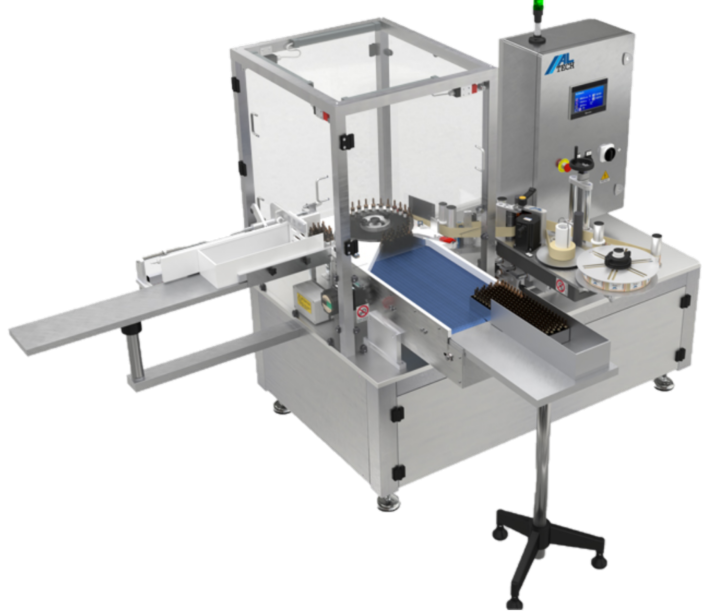

ALpharma B - pharmaceutical boxes labellers

Integrated system for printing and applying labels to shaped cases. For labelling with both bar code labels (tags, vignettes) and tamper-evident angle labels folded along the flaps (up to 200 products/min).

› This product line has a stainless-steel base and complete protective cabin.

› The belt conveyor consists of three sections with different speeds to accumulate the incoming boxes and then space them out by increasing the speed.

› On one side of the loading unit there are two motorised belts for aligning the products (speed synchronised with the first conveyor section) and another two faster ones to space out the products evenly.

› The labelling is performed on two sides when the boxes are stabilised by an upper motorised belt.

› The labellers (ALritma) have capacitive sensors for reading transparent labels.

› Label folding is performed by two shaped stainless steel plates and two rollers which press the folded part over the edge.

› At the end of the line there is an expulsion system for non-labelled products, activated by two special sensors (one for each side of the product) and a reject bin.

Technical specifications ALpharma B

Power supply – 400V 50 Hz three-phase | Power Consumption – 1 Kw | Performances up to 200 pcs/min

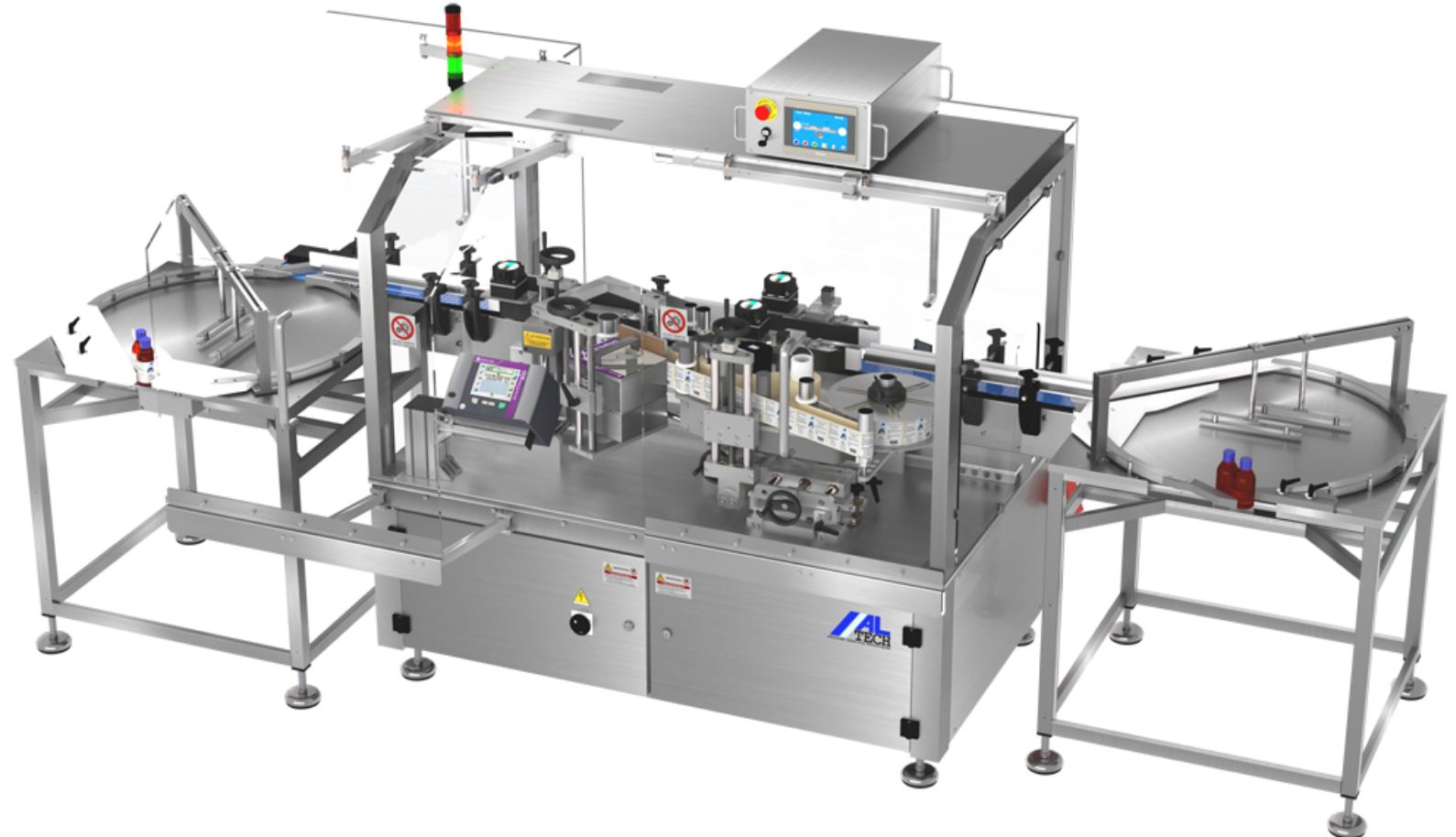

ALpharma C - wrap-around labelling machine

For in-line wrap-around labelling of small, cylindrical bottles. Speed: up to 250 products/min.

Available options:

• Overprinting with hot-foil or thermal-transfer printing

• Near end-of-reel and rewinder-full monitoring

• Near product monitoring

• Barcode checking

• Sensors to check for correct/performed overprinting, with print mark reading or camera

• Sensors to check that labelling has been correctly performed, with luminescence sensors or camera

• Expulsion of rejected products with check that expulsion has occurred and rejects box full monitoring

• Management of formats, alarms history and rejects.

Technical specifications ALpharma C

Power supply – 400 V 50 Hz three-phase | Power Consumption – 1 Kw | Performances up to 250 pcs/min

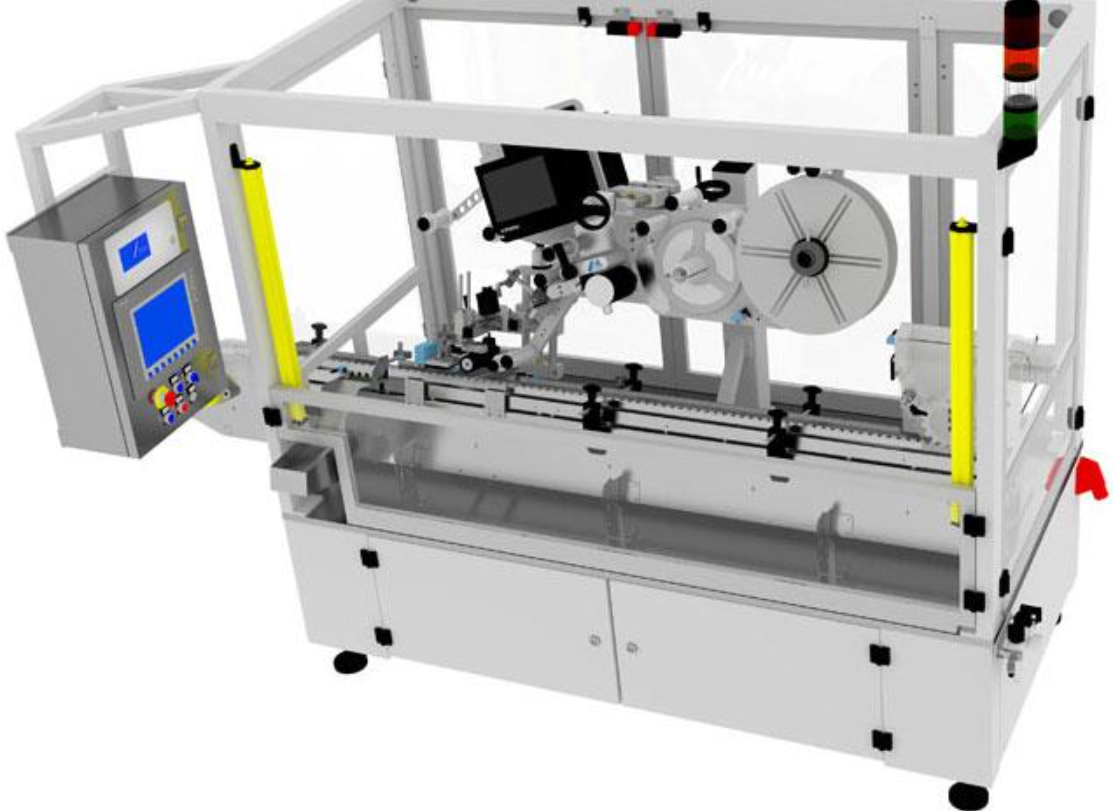

ALpharma CH - horizontal test tubes and vials labelling machine

Wrap-around labelling systems for particularly slim products (test tubes etc.), processed horizontally on an idle roller conveyor. Is available with automatic loader.

Available options:

• Overprinting with hot-foil or thermal-transfer printing

• Near end-of-reel and rewinder-full monitoring

• Barcode checking

• Sensors to check for correct/performed overprinting, with print mark reading or camera

• Sensors to check that labelling has been correctly performed, with luminescence sensors or camera

• Expulsion of rejected products with check that expulsion has occurred and rejects box full monitoring

• Management of formats, alarms history and rejects.

Pharmaceutical labellers

ALTECH’s proven experience in design of industrial labelling machines led ALTECH to develop the ALpharma line which labels, protects and checks pharmaceutical products (vials, cases and bottles).