Products

ALTECH ALline - Solid Base Labelling Systems

INQUIRYSolid Base Labelling Systems

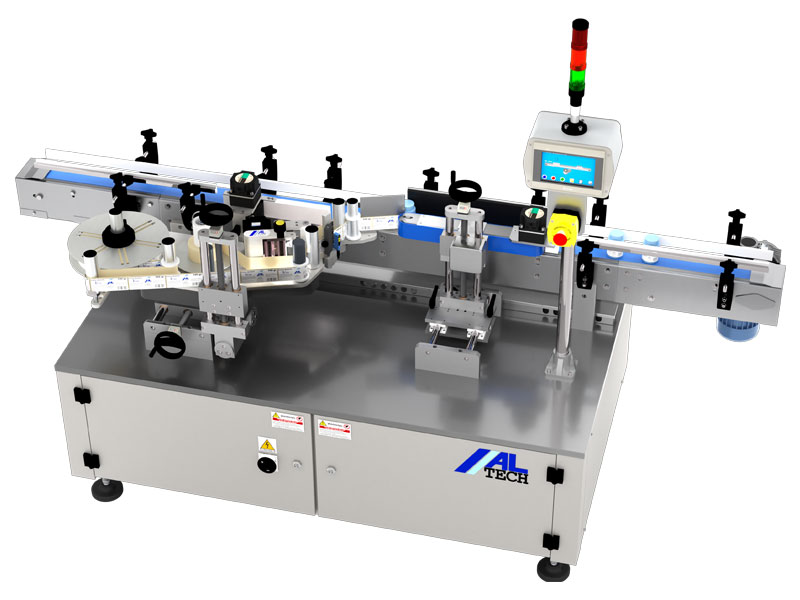

ALline C

High-Performance Wraparound Labelling System

ALline C is a high-performance, fully-featured in-line wraparound labelling machine for straight-sided (or slightly tapered) cylindrical products. These include plastic, glass or metal jars, vials and bottles, containing foodstuff, chemicals, cosmetic & pharmaceutical products, to name but a few.

ALline C

ALline C is an extremely robust and modular high-performance wraparound labelling machine, designed for in-line use (or standalone operation, usually with rotary infeed and outfeed tables) with virtually any cylindrical round product.

It can be configured in an almost infinitely variable way, with a choice of spacing systems, labelling heads and coding options. These are chosen according to the products to be labelled, the environment the machine will be placed, and the performance requirements of the application.

Typical label application operation speeds vary between 60-200 products per minute, dependent on the label and product dimensions, with the potential in some applications, to exceed 250 products per minute where a scroll spacing unit is employed (to guarantee a perfect regularity of product pitch).

At the heart of any ALline C labelling system is our advanced ALritma labelling head. Control of this device, along with all the other various elements of the machine, is operated via a standard 'machine visualisation' touch screen control system, mounted in an ergonomic upper position.

This sophisticated control system, allows complete label/product recipe setups to be stored and recalled (rather than just the parameters of the labelling head, as is usual in most competitor machines, or our lesser wraparound machines), with optimal speeds for the conveyor/wraparound and product pitch spacing stored as part of this recipe, along with the various position values of the devices (via counters schedule). This means you can be assured of both the perfect product setup and also consistency in label position between batches, so the product looks the same on the shelf.

Key Features

-

High-efficiency in-line labelling system designed for cylindrical containers.

-

Optional integrated rotary infeed and outfeed tables for independent use.

-

Exceptionally durable, fully enclosed frame with extendable chain conveyor and status beacon included as standard.

-

Accurate motion control with counters and calibrated scales on all axes.

-

Centralised management with visual control interface, enabling all setup parameters to be stored in a single recipe.

Technical information

| Power Supply | 400V 50 Hz three-phase |

|---|---|

| Power Consumption | 1 KW |

| Performances | Up to 500 pcs/min adjustable |

.gif)

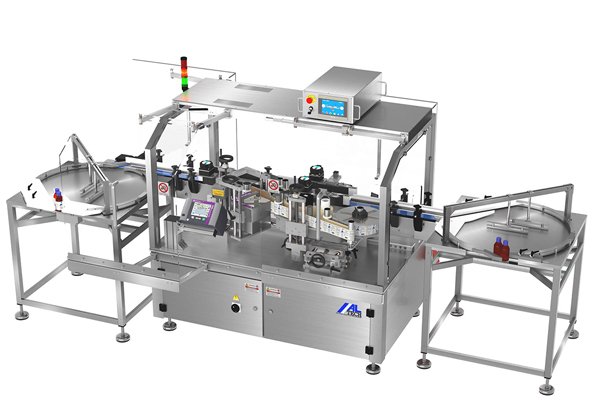

ALline C with Rotary Infeed and Outfeed

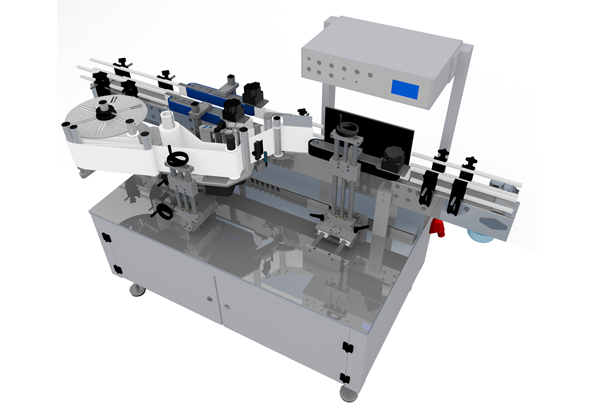

ALline C with Pots

ALline C with Extended Operation Labelling Head

Other models

ALline E

Advanced Front & Back Linear Labelling System

ALline E is a sophisticated, fully automatic labelling machine for rectangular or oval-shaped products. It applies both front and back labels simultaneously in a single product pass with exceptional precision and reliability.

ALline 3 Roller

Ultra-Precise Wraparound Labelling

The ALline 3-roller (also known as tri-roller or in-phase) wraparound system delivers outstanding labelling precision, enabling rotationally registered label placement on demand. It’s ideal for applications requiring maximum accuracy and repeatability.

ALline Horizontal

Horizontal Roller Conveyor Labelling System

This model offers high-accuracy wraparound labelling for cylindrical products positioned horizontally — ideal for items with unstable bases or where the base-to-height ratio is less than one-third. It ensures reliable alignment and consistent label application.

ALline Special

Multi-Panel, Tamper Tab & Customised Solutions

ALline Special systems are tailored for complex labelling needs, including multi-panel (2-, 3-, or 4-face) applications, high-speed watchstrap and tamper-evident label placement, as well as nonstop continuous-running configurations for demanding production environments.