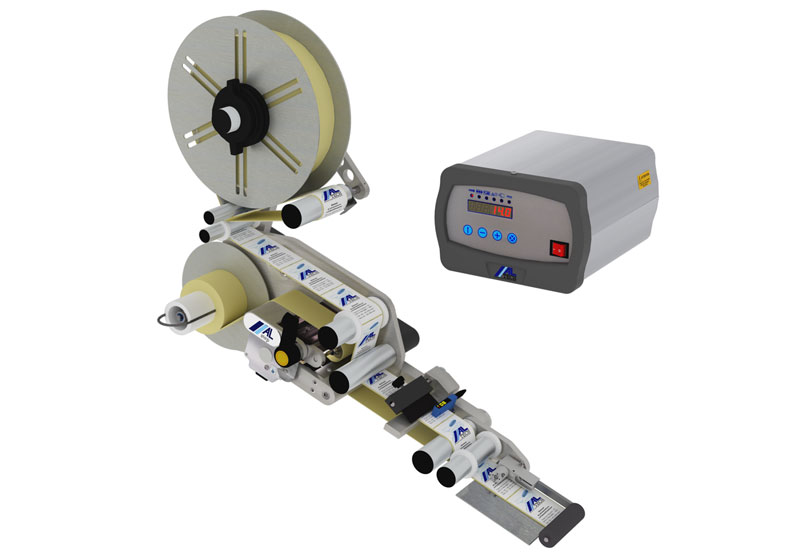

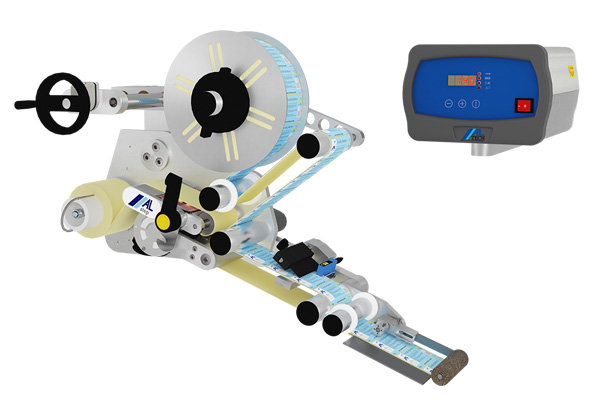

ALtech ALstep – Economical Label Applicator

Key Features

- Compact, cost-effective “workhorse” label applicator range

- Economy “E” series up to 18 m/min; Performance “S” series up to 30 m/min

- Standard widths: 100 mm (S), 200 mm (M); 100 mm (E) for the economy version

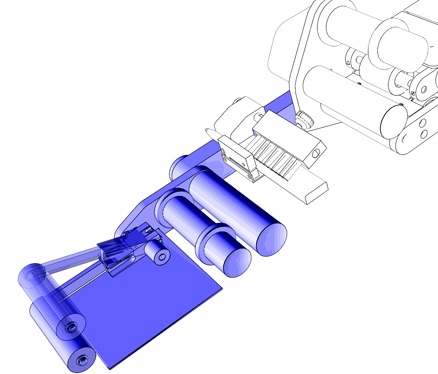

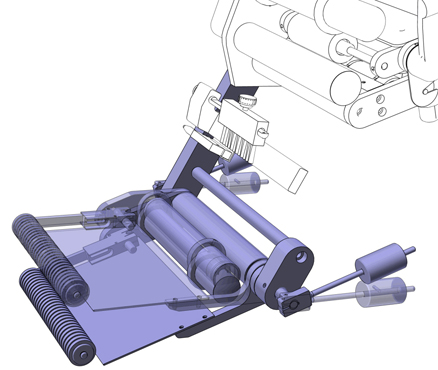

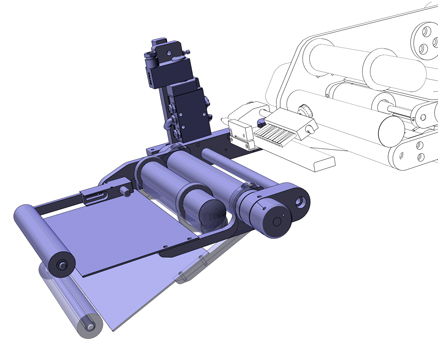

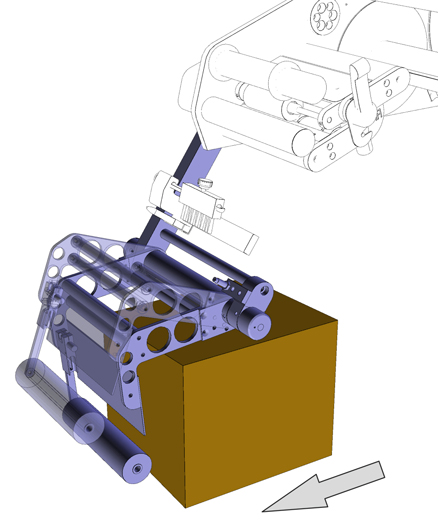

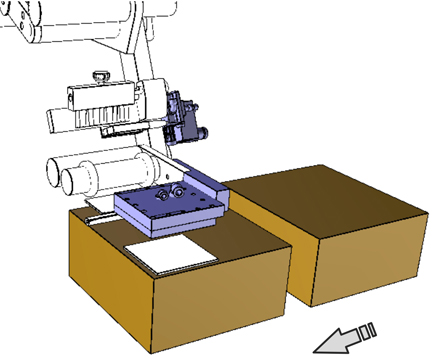

- Modular design with application systems for almost any labelling task

- Fanless anodised aluminium control box for reliable operation in harsh environments

Overview

The ALstep features a durable, versatile mechanical design that can be mounted in any orientation. Side-access web threading and a clearly numbered web path make changeovers fast and effortless, even in tight spaces.

Available in two sizes — S (up to 100 mm label width) and M (up to 200 mm) — ALstep achieves dispensing speeds up to 30 m/min (20 m/min for the M version), driven by a high-performance stepper motor and precise web tension control.

Its modular construction offers a wide range of configuration and application options, making it adaptable for demanding labelling tasks.

Label Application Options

Build & Customisation

If a standard solution isn’t available, our team can engineer custom label application systems or machine configurations for your process.

ALstep applicators support label reels up to 300 mm diameter (approx. 450 m) on a 76 mm industry-standard core for extended, uninterrupted operation.

The unwind/rewind holding disks and separate LCD control unit are made from durable anodised aluminium; the disks are virtually unbreakable, and the fanless control box ensures reliable performance in demanding industrial environments.

Technical Specifications

| Specification | Details |

|---|---|

| Label Width | Max 100 mm (E & S) / Max 200 mm (M) |

| Control | LCD display with 6 function buttons |

| Standard Alarms | End of roll / Web break |

| Pieces Labelled Counter | Standard |

| Unwind Unit Diameter | 300 mm (S & M), 220 mm (E), 76 mm core (all models) |

| Batch Coder (TT, TIJ, CIJ, Hotfoil) | Optional |

| Full Inline TT/DT Printer | Optional (e.g., Sato / Zebra) — ALstep T |

| Pneumatic Application | Optional |

| Max Line Speed | 18 m/min (E), 30 m/min (S), 20 m/min (M) |

| Label Positioning | Electronic (mm) |

| Missing Labels Recovery | Standard |

| Transparent Label Sensor | Optional |

| Near End of Reel Check | Optional |

| Encoder | Optional |

| Power Consumption | 400 W |

| Power Supply | 240 V – 50 Hz |

Models