Products

Operation Guidance

INQUIRY| Smart Guide For checkweighers to function properly, operation checking must be performed correctly at each stage of the daily operation: at start-up, during production, and at the end of production. These procedures, although necessary, are not always strictly followed due to the time and effort involved. Smart Guide navigates operation check and maintenance procedures in an easy-to-understand format. If a procedure was performed incorrectly, Smart Guide will not allow to proceed further, ensuring correct operation management. |

|

|

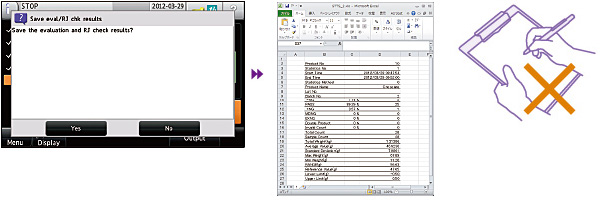

E-Daily Report |

|

|

Product Registration Navigation simplifies parameter setting procedures with step-by-step illustrated instructions. On-screen illustrations help you understand each key procedure. If performed improperly, the navigation stops for corrective action. |

|

Useful features: USB and Ethernet interfaces are equipped as standard features.Both metal detector and checkweigher are controlled by the standard touch screen control panel.

Checkweigher

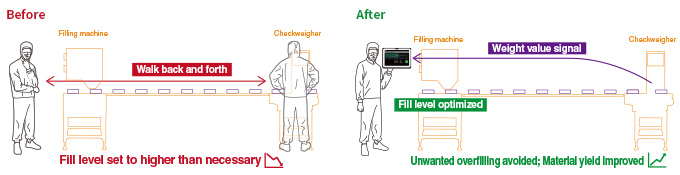

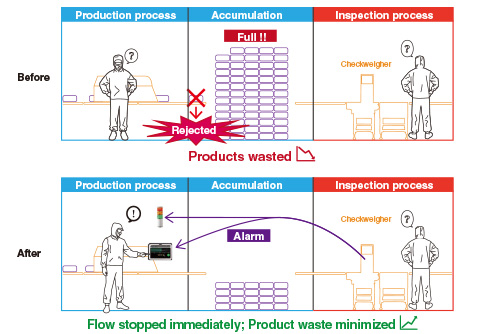

【Mobile Monitor for Checkweigher】

Remote checkweigher operation monitoring helps to optimize overall line efficiency.

Enlarged bar Individual weight and evaluation |

X-bar Long-term trending |

Graph Short-term trending |

Statistics Total count and statistics |

|

Operating system

|

Android™ 4.0, 4.1

|

|

Connectable equipment

|

Checkweigher SV series and SSV series

|

|

Maximum product number

|

100 products (for both SV and SSV)

|

|

Connectable equipment number

|

6 units

|

|

Maximum processing speed

|

1,000 pieces/min (depends on tablet capacity)

|

|

Maximum display data

|

1,000 data (batch number, individual data number)

|

|

Functions

|

Alarm display function (mean value, rejection rates, metal NG, +NG, -NG), Sound notification function, Signal tower light alarm notification function

|

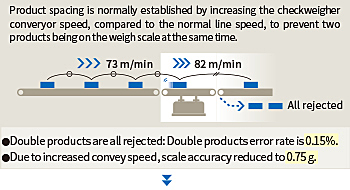

Anritsu proprietary technology: SMF

| 1) Accurate weighing Conventional checkweighers use the weigh cell signal, after signal processing, to determine the weight of each product as it passes over the weigh table. If two packs are on the weigh table at the same time, a "double product error" will occur and the system is forced to reject both products since each individual product weight cannot be determined. Anritsu SSV series checkweigher advancements use innovative signal processing, multi-threaded filtering, in conjunction with improved scale resolution to minimize "double product errors". This simultaneously minimizes unnecessary rejects and maximized line productivity. |

Good conveying condition Two packs on scale  |

|

2) Rejection down, yield up with SMF

|

Conventional checkweigher SSV checkweigher equipped with SMF  |

| Newly developed force balance is equipped in high accuracy models. Minimum scale value is 0.001 g. Maximum accuracy is +/- 0.010 g. Resolution quadrupled (in-house comparison). Temperature resistance improved. Anritsu's new force balance load cell has achieved the verification scale interval of e=0.05 (Minimum weighing: 3 g, Maximum weighing: 100 g). Our new force balance load cell obtained the highest standard of MID (Measuring Instrument Directive), Class XII. |

|