News

Quality control, coding and packaging equipment for manufacturers

Nord Systems helps manufacturers select, implement and support industrial equipment for product inspection, checkweighing, coding, packaging and printing. Individual approach — tailored to each company and each production line.

We visit your facility, demonstrate equipment in operation and can test it with your products. Available in Latvia, Lithuania and Estonia.

Get practical insights on quality control, coding and packaging solutions, examples from production sites, special offers and product updates. No spam — only useful content.

SubscribeX-ray Inspection: 3 Lesser-Known Capabilities

Modern X-ray inspection machines offer more than standard metal detection. Systems such as the Anritsu XR76 Series, XR75 DualX for fish and poultry, and dual-energy models combine high-resolution imaging with hygienic stainless-steel construction. In practice this means the equipment can be safely cleaned with high-pressure washdowns, while long-life components keep uptime stable. Today’s units are built for demanding food environments and are designed to make everyday maintenance easier and safer.

Hygienic Design and Easy Maintenance

X-ray units often operate in challenging food processing conditions, so simple, reliable cleaning is essential. Leading models use sealed, stainless-steel housings with IP66–IP69K ratings, allowing full washdown and pressure washing. They include features such as tool-free disassembly and robust cooling systems that withstand harsh environments. This helps reduce service needs and keeps production running smoothly.

-

Washdown-ready build: Fully sealed stainless-steel enclosures designed for high-pressure cleaning.

-

Long-life components: Cooling systems and durable X-ray tubes reduce wear and unplanned downtime.

-

Quick cleaning: Smooth surfaces and tool-free access allow operators to clean the machine thoroughly in minutes.

Together, these design elements allow intensive cleaning routines without risking equipment damage or compromising food safety.

Versatile Quality Checks

Modern X-ray systems do much more than spot foreign objects. Because they image the inside of each product, they can verify what is actually in the package. For example, they can detect whether pastries are properly filled, whether candies are missing inside sealed wrappers, or whether a package is underfilled or completely empty — all without using weight as the primary indicator.

-

Shape and fill inspection: Identifies missing, broken, cracked, or underfilled items by analyzing internal structure.

-

Content verification: Confirms the presence of product inside every package, preventing empty or half-filled packs from reaching customers.

-

Advanced imaging: Dual-energy technology compares high- and low-energy X-ray images to distinguish product from contaminants, especially useful in sectors like fish and poultry.

This allows 100% inline inspection without slowing the line and helps eliminate packaging errors that would otherwise go unnoticed.

Enhanced Contaminant Control

Contaminant detection remains the foundation of X-ray technology, but today’s systems provide far more sensitivity than earlier generations. They can identify very small metal fragments, glass pieces, stones, dense plastics, rubber, or even bone fragments — even when these contaminants overlap other items inside the package.

-

High sensitivity: New sensors and algorithms detect small or low-density hazards that older systems miss.

-

Broad hazard range: Detects metal, glass, stone, plastic, bone, cartilage, and other unexpected objects.

-

Overlap detection: Advanced imaging allows accurate inspection even in layered or overlapping products.

By combining straightforward maintenance, precise detection of product quality issues, and robust contaminant control, modern X-ray inspection systems take on multiple roles at once. They strengthen safety, support consistent production, and help prevent both quality losses and unnecessary rejects — all within a single inspection point.

How to choose an inkjet printer for production?

Inkjet printers have become an essential part of industrial product marking across European manufacturing facilities. These modern systems provide fast, precise, and versatile marking on a wide range of surfaces. However, choosing the right printer raises many questions — what speed is required, which inks to use, how to calculate operating costs, and how to ensure the printer runs reliably.

Which materials can be printed on with an inkjet printer?

Modern inkjet printers are highly versatile and can print on almost any material, but selecting the correct type of ink is crucial.

Porous surfaces (cardboard, paper, wood, textiles):

These materials work well with water-based or solvent-based inks. The ink absorbs into the surface and dries quickly, ensuring strong adhesion without additional treatment. This is the most common application in packaging marking.

Smooth surfaces (plastic, metal, glass, laminated cardboard):

These require special inks with stronger adhesion — typically UV inks or oil-based inks. They dry faster and provide excellent resistance to abrasion, moisture, and temperature fluctuations. UV inks are especially popular in the food and beverage industry.

Combined solutions:

If different packaging materials are used in production, modern printers allow switching ink cartridges depending on the need. For example, NordSystems offers universal printers that support multiple ink types within one system.

How fast should the printer be to match the production line?

Print speed is one of the most critical factors. If the printer is too slow, the entire production line must be slowed down, or products will pass unmarked.

Speed calculation:

If your conveyor moves at 0,5 m/s and a product is 20 cm long, the printer has only about 0.4 seconds to print all information. Therefore, choosing a printer with 20–30% speed reserve is essential.

Standard categories:

- Low performance: up to 30 m/min (manual or small production)

- Medium performance: 60–100 m/min (standard production lines)

- High performance: 150–300 m/min (large-scale industrial production)

Practical solutions:

If the conveyor speed is fixed and the printer cannot keep up, you can:

- Reduce the print area (print only essential data)

- Install two printers in sequence

- Slow down the belt only in the printing zone

Specialized suppliers in the Baltics, such as NordSystems, can help calculate the optimal printer for a specific production line.

What hidden costs are often forgotten?

Many companies focus only on the purchase price of the printer, but the real expenses appear during operation.

Consumables:

Ink and solvents are the largest ongoing expense. Lower-grade printers often use more expensive or less common original inks, increasing long-term cost. Important: never use unbranded, incompatible, or cheap “China” inks — they can damage the printheads, distort colours, and cause malfunctions, leading to repairs. Printers are designed to work with certified inks from the manufacturer. In most cases, non-original inks simply will not work.

Maintenance and repairs:

- Printhead replacement (every 6–18 months) — medium cost

- Preventive maintenance (2–4 times per year) — low to medium cost

- Unplanned repairs — can be very expensive, especially if low-quality consumables were used

Downtime costs:

If the printer breaks down and no spare parts or service are available, the entire production line stops. Even one day of downtime can cost more than the printer itself.

Example:

A low-grade printer with higher ink and maintenance costs may cost significantly more after 3 years than its initial purchase price.

A higher-quality printer with lower operating expenses and more stable performance is often the more cost-effective long-term solution.

Therefore, it is essential to choose a supplier with a strong service network. In Latvia and the Baltics, companies such as NordSystems provide spare parts and fast technical support, reducing downtime risks.

Is the printer difficult to use? Is special training required?

The good news — modern industrial printers are designed for easy operation even by staff without technical education.

Daily operation:

The operator usually performs only three tasks:

- Turns on the printer (one button)

- Selects a design from saved templates (touchscreen)

- Monitors ink levels (never use non-original or incompatible inks!)

All complex processes — printhead positioning, ink delivery, temperature control — run automatically.

Maintenance:

- Daily: wipe off dust (2 min)

- Weekly: printhead cleaning (10–15 min, automated)

- Ink replacement: plug-and-play cartridges (5 min)

Training:

Reliable suppliers provide:

- Full operator training during installation (2–4 hours)

- Remote support by phone or video

- Annual refresh training

Practical example:

NordSystems typically trains 2–3 operators on installation day. After a week, they perform all daily operations independently. For complex issues, remote technical support is available.

Safety:

Modern printers include safety features:

- Automatic low-ink warnings

- Misuse protection

- Protective covers to reduce injury risk

Conclusion: if an operator can use a smartphone, they can use a modern industrial printer.

How to know if the printer is suitable for your products?

The best way is to request a demonstration with your products before purchase.

Trial period:

Some suppliers offer rental or trial options for 2–4 weeks. This allows testing the printer under real production conditions.

References:

Ask the supplier for contacts of similar companies in your industry. Conversations with existing customers provide real insight into daily printer performance. NordSystems often arranges visits to similar printers already operating in other factories.

Summary: what to consider when choosing a printer?

✅ Material compatibility — ensure the printer supports your packaging materials

✅ Print speed — choose with 20–30% reserve

✅ Total cost — evaluate ink, maintenance, and downtime costs for 3–5 years

✅ Original inks — never use cheap or unbranded inks

✅ Service availability — ensure local service and spare parts are easily accessible

✅ Ease of use — operators should be able to work without complex training

Choosing the right printer will not only improve marking quality but also reduce costs and increase production efficiency.

NordSystems offers a wide range of inkjet printers for various production needs in Latvia and across the Baltics. Contact us for a consultation.

info@nordsystems.eu

+371 67717575

Metal Detection & X-Ray Inspection in EU Food/Grain Industries: Regulations, Practices & Challenges

Metal Detection & X-Ray Inspection in EU Food Industry

Metal Detection & X-Ray Inspection in EU Food Industries: A Closer Look at Regulations and Real-World Challenges

Industrial metal detectors and X-ray inspection systems serve as critical gatekeepers in Europe's food and grain industry. These sophisticated machines prevent foreign object contamination, protect consumers, and help manufacturers comply with stringent food safety standards. But navigating the web of EU regulations, managing calibration schedules, and finding qualified service technicians presents ongoing challenges for food producers across the continent.

Industrial metal detectors and X-ray inspection systems serve as critical gatekeepers in Europe's food and grain industry. These sophisticated machines prevent foreign object contamination, protect consumers, and help manufacturers comply with stringent food safety standards. But navigating the web of EU regulations, managing calibration schedules, and finding qualified service technicians presents ongoing challenges for food producers across the continent.

The Regulatory Framework: What EU Food Producers Must Know

While EU law doesn't explicitly mandate metal detectors or X-rays in every facility, the HACCP (Hazard Analysis and Critical Control Point) requirements under Regulation EC 852/2004 obligate producers to control physical hazards. If metal or foreign materials are identified as risks, suitable detection equipment must be in place.

For X-ray systems specifically, Directive 1999/2/EC permits their use provided the absorbed dose remains below 0.5 Gray at maximum 10 MeV energy. This ensures products don't require special labeling while allowing effective contaminant detection. Radiation leakage standards cap emissions at approximately 0.5 µSv/hour at 5 cm from the machine, making them safe for daily use.

Beyond legislation, private food safety standards drive stricter requirements. BRCGS and IFS certification schemes require proper validation, routine testing, and calibration of detection equipment at critical control points. IFS Food Version 7 explicitly mandates annual verification with thorough performance tests and documentation. These standards demand proof that new detectors achieve required sensitivity before use and undergo ongoing monitoring through frequent in-process checks.

Testing Frequency: Balancing Safety and Production

Determining optimal testing schedules balances regulatory compliance with operational efficiency. Industry practice divides maintenance into two levels:

Daily Operational Checks

Best practices call for testing at minimum at start and end of each shift, plus after product changes or machine adjustments. Higher-risk lines may test every 2-4 hours during production. Many facilities insert standardized test pieces to confirm proper rejection of contaminated products. Any maintenance or repairs trigger immediate retesting.

Annual Professional Calibration

Beyond daily checks, systems require comprehensive calibration at least once yearly by qualified personnel. Industry guides suggest scheduling this 2-6 months before audits, allowing time for repairs. Technicians use certified test standards to tune sensitivity and verify detection targets. X-ray systems need similar annual normalization of detectors and settings, with re-validation required whenever new products are introduced.

X-Ray Systems: The Radiation Safety Imperative

X-ray equipment introduces additional regulatory complexity due to ionizing radiation. Under EU Directive 2013/59/Euratom, member states require companies to undergo registration and implement radiation protection measures before operation.

Food processors must consult a certified Radiation Protection Expert (RPE) or Radiation Protection Adviser (RPA) who conducts risk assessments, verifies shielding, and drafts "Local Rules" for safe operation. The expert establishes monitoring requirements and classifies areas around machines as controlled or supervised zones.

On-site, trained Radiation Protection Supervisors (RPS) oversee daily compliance. Many jurisdictions require an RPS present whenever X-rays operate. Devices must be registered with national regulators, and regular radiation surveys verify emissions stay below legal limits. These specialized requirements differentiate X-ray systems from metal detectors, which general technicians can handle.

The Technician Shortage: A Growing Challenge

A critical bottleneck emerges in the availability of qualified service technicians across Europe. As food companies expand their use of advanced inspection systems, demand for skilled field engineers has outpaced supply. The complexity of modern systems—requiring electrical, mechanical, and software expertise plus food safety knowledge—limits the talent pool.

Geographic distribution compounds the problem. While Western Europe enjoys 24-hour response times due to dense technician networks, Eastern and Southern Europe face spottier coverage. In smaller markets like the Baltics, just a handful of qualified engineers cover entire countries. NordSystems, operating from Riga and Tallinn as the exclusive Anritsu distributor in Estonia, Latvia, and Lithuania, exemplifies this challenge—serving a wide territory with limited regional specialists. When machines fail in remote locations, facilities often depend on remote support or wait for experts traveling from other countries.

Companies are responding by training internal maintenance personnel for first-line troubleshooting and investing in remote diagnostic tools and predictive maintenance features. However, experienced inspection system technicians remain in high demand and short supply across the continent.

Lessons from the Field: What Practitioners Say

Industry forums reveal recurring challenges that complement official guidelines with practical wisdom:

False Alarms

Products with high salt or moisture trigger false positives in metal detectors, while X-ray units may falsely reject packages due to density variations. Proper setup—using phase adjustment for saline products or tuning X-ray algorithms—reduces waste and prevents operator frustration.

Training Gaps

Human error remains a major concern. Mis-calibrated detectors, skipped test procedures, or improper responses to rejects stem from inadequate training. Manufacturers increasingly offer online training academies to certify staff competence and reduce downtime.

Documentation Discipline

Auditors show little tolerance for incomplete test records or non-certified test pieces. Quality managers now use color-coded, certified test wands with supplier documentation to satisfy due diligence requirements during BRC, IFS, and customer audits.

Service Providers: Who Keeps the Systems Running?

Europe's service ecosystem mixes manufacturer-direct operations with regional distributors. Major global manufacturers like Mettler-Toledo, Sesotec, Loma Systems, Minebea Intec, Anritsu, and Ishida maintain European networks providing end-to-end service from installation to annual calibration.

Regional distributors fill crucial gaps in smaller markets. NordSystems exemplifies this model as Anritsu's Baltic partner, supplying metal detectors, X-ray units, and checkweighers while providing on-site testing, calibration, and training services throughout Estonia, Latvia, and Lithuania. Their local presence enables faster response than distant European teams could achieve.

Independent service companies—accredited testing firms and certified consultancies—offer third-party verification, particularly valuable for facilities with mixed equipment brands seeking unified validation services.

Service providers typically offer annual maintenance contracts including preventive visits, emergency call-outs, and phone support. In Western Europe, 24-hour response times are standard; Eastern Europe sometimes requires backup units at critical control points as insurance against longer service delays.

Sources & References

- EU Directive 1999/2/EC on ionizing radiation use for food inspection; Sesotec X-ray safety overview (sesotec.com)

- FSNS guidance on metal detector testing frequency (fsns.com); Loma Systems best practices (planautomation.com)

- Sesotec guide on BRC testing triggers; IFS Food v7 verification requirements (sesotec.com)

- Loma Systems guidance on X-ray regulatory steps (loma.com); EU Basic Safety Standards (2013/59/Euratom) (stresstech.com)

- Plan Automation tips for GFSI audits (planautomation.com); Industry report on skilled labor shortage (cognitivemarketresearch.com)

- Loma press release on training benefits (fdiforum.net); Practitioner discussions on testing frequency (planautomation.com)

- Cognitive Market Research report listing key inspection system providers; NordSystems noted as Baltic provider (Anritsu dealer) (cognitivemarketresearch.com, youtube.com/@NordSystems)

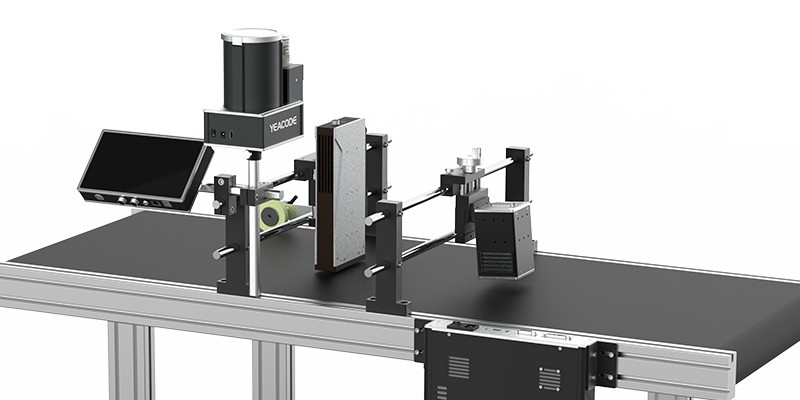

Comparison of Printing Methods in Woodworking

The marking of wooden pallets, boards, and other products is mandatory for international trade (ISPM-15/EPAL). Traditionally, companies used branding irons — heated metal stamps that leave an imprint on the wood surface. Today, more and more factories across Europe and the Baltics are switching to high-resolution inkjet printers such as Yeacode, distributed in the Baltics by NordSystems. These systems allow faster, safer printing with significantly lower operating costs. Overview of Use Advantages Disadvantages Prevalence Technology Main Advantages Limitations The heat-branding method is still used by small producers but is energy-intensive, slow, and risky. Modern inkjet printers provided in the Baltics by NordSystems enable production that is faster, safer, and up to 80 % more cost-efficient. They are fully compatible with EPAL and ISPM-15 requirements, allow digital data printing, and significantly improve production efficiency.Comparison of Printing Methods in Woodworking: Heat Branding vs Inkjet Marking (Yeacode)

Introduction

Heat Branding

Inkjet Marking (e.g. Yeacode)

Numerical Comparison (Typical Line)

Factor

Heat Branding

Inkjet (Yeacode)

Marking time

~10 s

~0.2 s

Productivity

up to 1 000 pcs/h

up to 10 000 pcs/h

Energy consumption

~36 kWh/shift

~0.8 kWh/shift

Unit cost

~€0.015

~€0.002–0.003

Downtime

30–60 min/day

< 5 min/day

Safety

High fire risk

Flameless, safe environment

Summary

Packaging and Labeling Errors: Lessons from Real EU Case Studies

Packaging and labeling errors are among the most common causes of product recalls across Europe. In food, beverage, pharmaceutical, and cosmetics industries, even small defects — such as incorrect labels, missing allergens, or weight inconsistencies — can lead to wasted products, legal issues, and loss of consumer trust.

Regulatory data shows that labeling and packaging problems are responsible for a significant share of recalls every year. Many of these incidents could have been prevented with consistent quality control and reliable inspection systems on the production line.

Food and Beverage Industry

In the food sector, errors like missing allergen information or inaccurate net weights are among the top reasons for recalls.

A recent case in the Netherlands involved a brewery recalling one of its specialty beers because the allergen “oats” was not declared on the label. In another example, a UK retailer had to withdraw nearly 70,000 packs of garlic bread when tests showed the weight was up to 20% lower than indicated on the packaging.

Such cases highlight how critical checkweighers and automated labeling systems are.

NordSystems checkweighers continuously monitor product weights in motion, instantly removing any under- or overweight items. Combined with precise labeling and printing systems, manufacturers can ensure every package meets declared specifications before shipment — reducing waste and protecting compliance.

Pharmaceutical Industry

The pharmaceutical sector operates under some of the strictest packaging and labeling regulations in Europe. Even minor labeling discrepancies can pose safety risks.

In one widely publicized incident, more than 100,000 packs of paracetamol were recalled after the blister packs were printed as “Aspirin 300 mg.” Although the medicine inside was correct, the packaging error created serious confusion and potential health risks.

This kind of issue could have been avoided through tighter packaging-line control. NordSystems printing and labeling equipment helps ensure that batch data, expiration dates, and dosage information are consistently applied and readable. X-ray and metal detection systems further enhance line safety by checking for contamination before products are boxed, ensuring full compliance with GMP standards.

Cosmetics Industry

In cosmetics, labeling accuracy is equally critical. Ingredient lists, allergens, and SPF values must match the actual product content.

Several EU recalls have been linked to creams and lotions where the SPF was lower than stated or fragrance allergens were not disclosed. These issues not only breach EU labeling regulations but also harm consumer trust.

NordSystems labeling and printing solutions ensure consistent, high-quality label application, while checkweighers confirm that each unit meets correct fill weight. This combination minimizes the risk of packaging inconsistencies and helps maintain brand reputation in a highly competitive market.

Why Consistent Inspection Matters

Across all industries, the lesson is the same: errors caught too late become expensive problems. Each mislabeled or incorrectly filled product that leaves the factory increases the risk of recalls, rework, and wasted materials.

By integrating checkweighing, labeling, printing, X-ray, and metal detection systems, manufacturers can detect inconsistencies at multiple stages of production — before the product reaches the customer. These systems form the backbone of reliable quality control and compliance within modern factories.

Conclusion

From a missing allergen declaration to an incorrect dosage label or underfilled package, small packaging errors can have major consequences.

NordSystems helps manufacturers prevent these issues by providing reliable inspection and marking systems that ensure accuracy, safety, and efficiency across production lines.

NordSystems solutions can help your factory detect errors before they reach the shelf.

Comparison of Marking Methods in the Woodworking Industry: Heat Branding and Inkjet Printing

Introduction

Marking wooden pallets, boards, and other products is a mandatory requirement in international trade (ISPM 15/EPAL), and the mark provides information on origin, treatment, and quality. Traditionally, the woodworking industry used heat branding — a heated brass stamp leaves an imprint on the wood surface. Today, more and more companies are switching to high-resolution inkjet printers, such as the Yeacode and Sojet MoEco series, which can print on wood at high speed with minimal resource consumption. This study compares the advantages, costs, and suitability of both methods for woodworking companies in the Baltics and Europe.

Heat Branding

History and Applications

- Heat branding has been used for centuries; artisans burned stamps with hot irons, whereas today pallets and other wooden products are typically marked with inkjet or ink-roll type stamps.

- ISPM 15 and EPAL standards require export pallets to be treated and marked; the classic method is heat branding — a metal stamp is heated to about 500 °C and pressed onto the pallet.

- The method is popular in small plants where investment in automation is not feasible; however, large factories in Europe increasingly choose inkjet printing systems.

Advantages

- Low capital expenditure — a simple device (brass stamp and gas or electric heater) is relatively inexpensive.

- No ongoing spend on inks or consumables — the stamp can be used for years as long as the mark layout does not change.

- Suitable for small volumes or craft production.

Drawbacks

- High energy consumption and cost — heaters often contain several 0.75 kW coils. Typically there are six elements, so the total power is about 4.5 kW, maintained continuously to keep the stamp at ~500 °C.

- Slow and labor-intensive — each marking takes ~10 seconds; operators manually position the block and press the stamp.

- Safety risks — hot metal and open flame increase fire risk and require additional insurance.

- Low flexibility — each stamp is fixed; different text requires a new stamp. Not suitable for variable serial numbers, dates, or QR codes.

- Quality issues — heating chars the wood; soot and fumes pollute air and may irritate airways or skin. This is considered hazardous work, so employers must provide extra health insurance, regular check-ups, and certain work-time limits; EPAL blocks are not always perfectly smooth, so branded marks can sometimes be illegible.

- High insurance and safety costs — soot and hot metal require extra fire-safety equipment, staff training, and special workwear.

Use in Europe and the Baltics

In Latvia and the other Baltic states, traditional heat branding remains common in smaller companies — stamps are cheap and require no automation. However, in more advanced European countries (Germany, Belgium, the Netherlands, etc.) larger plants are increasingly abandoning heat branding because it slows production and poses safety risks. Paletten Service (Hamburg/UK) reports in a case study that their heat-branding system was “outdated, unsafe, and slow,” which significantly increased insurance costs.

Inkjet Marking

Technology Overview

Inkjet printers use different technologies to jet ink onto wood or other surfaces. The main types are: Thermal Inkjet (TIJ), which delivers high resolution and uses compact cartridges; Piezo Inkjet (PIJ), suitable for larger character printing with continuous ink supply; and Continuous Inkjet (CIJ), in which ink droplets are continuously generated and deflected onto the surface, enabling very high-speed printing on moving lines.

Modern industrial solutions, such as Yeacode, combine inkjet technology with UV curing, ensuring instant drying even on lacquered surfaces.

Yeacode — EPAL-Certified Solution

Yeacode printers (81, 84, and 8D series) are purpose-built for wood marking and certified to EPAL requirements. Key parameters and benefits:

- High resolution — up to 600 dpi for clear EPAL or HT stamps, QR codes, and serial numbers.

- Tall print height — 54.1 mm with one printhead; up to 216 mm with four printheads.

- High production speed — up to 260 m/min; 81 and 84 series 0–150 m/min.

- Ink versatility — water-, oil-based, or UV inks, incl. UV-LED curable inks that dry instantly.

- Wide data range — barcodes, dates, counters, logos, and database fields.

- Modularity and flexibility — printheads can be combined; up to four heads per controller.

- Automatic ink management — MCISS auto-detects ink type, monitors level, and ensures stable supply.

- Low power consumption — 24 V/5 A PSU (≈ 120 W); LED lights only during marking, so average power is ~30 W.

Advantages

- Very fast and flexible production — no stamp heating or metal die changes. Text or logo is changed on-screen; printing starts immediately. No line stops to change the mark format.

- Low energy use and minimal maintenance — LED-UV curing consumes roughly a tenth of the energy compared to heat branding, and Yeacode’s continuous ink feed reduces downtime.

- High print quality and durability — 300–600 dpi yields crisp, smudge-resistant prints; UV inks resist moisture and sunlight.

- Safety and environment — no open flame or high temperatures; reduced fire risk and less soot/fume pollution. Inkjet systems use mineral-oil-free inks with lower VOC emissions.

- Lower insurance and safety costs — no fire risk; operators avoid hot equipment.

- Variable data printing — date/time codes, serials, QR codes, etc. can be automated, which is impossible with heat branding.

- Fast start-up and minimal downtime — modern printers start in seconds, boosting line efficiency.

Drawbacks

- Higher initial investment than a simple branding iron. However, it pays back through low running and labor costs.

- Dependence on consumables (ink) — ensure inks comply with EPAL/ISPM 15 and have proper certification.

Adoption and Demand in Europe

Large European pallet manufacturers and logistics companies (e.g., Paletten Service in Germany/AJK) are already transitioning to inkjet technology. A Paletten Service study concluded that implementing the Diagraph IJ4000 reduced total marking costs by over 50 %, delivered higher print quality, and improved production flexibility. At Quint-C Pallet Company (USA), an industrial inkjet system delivered a 15 % production speed increase, 80 % cost savings, USD 45,936 annual savings, and 339 % ROI. These outcomes show that large plants in Europe and North America gladly invest in inkjet because it pays back quickly and provides competitive advantage.

In the Baltics, inkjet availability is growing rapidly. Nord Systems SIA in Latvia supplies Yeacode and Sojet MoEco printers and has delivered a certified EPAL marking solution — Yeacode 8D — meeting EPAL technical requirements with up to 600 dpi and 260 m/min. This enables Baltic pallet makers to match Western Europe in quality and efficiency.

Cost and Energy Analysis

Energy Consumption

Table 1 shows approximate energy use and cost comparing heat branding to an inkjet printer. The branding unit uses 6 × 0.75 kW heaters running all day; the inkjet LED lamp is on only during printing (about 7.5 % of the time)

|

Indicator |

Heat Branding |

Inkjet (Yeacode) |

Calculation Basis |

|

Total power |

~4.5 kW (6 × 0.75 kW heaters) |

~0.45 kW (LED + printhead); effectively active only 7.5 % of the time |

Based on Timbermark data |

|

Annual energy use (8 h/day, 22 days/month) |

≈ 9504 kWh |

≈ 71 kWh (average) |

4.5 kW × 8 h × 264 days = 9504 kWh; 0.45 kW × 7.5 % × 8 h × 264 days ≈ 71 kWh |

|

Annual electricity cost (0.2 €/kWh) |

≈ 1,900 € |

≈ 14 € |

Europe-wide average electricity price as of 2025 |

Conclusion — heat branding consumes ~133× more energy and costs nearly €2000 per year, while an inkjet printer can operate with almost no additional energy cost.

Labor and Productivity Comparison

|

Factor |

Heat Branding |

Inkjet (Yeacode/Diagraph) |

Sources |

|

Marking speed |

One operation ~10 s; ~6 pallet blocks per minute |

Inkjet up to 260 m/min; can mark double-sided blocks in continuous flow |

Timbermark, Yeacode specifications |

|

Labor |

Operators required to heat, position, and swap stamps; high workload |

Automated in-line process; operator supervises the printer and can do other tasks |

Quint-C and Paletten Service cases |

|

Flexibility |

No info change without a new stamp; data codes not possible |

Variable data, barcodes, QR codes, date/time from the HMI |

Yeacode specification |

|

Maintenance |

Heater resistors wear; charring creates soot; regular cleaning required |

Low maintenance; continuous ink system, printhead cleaning; ink cost is modest |

UBS and Yeacode descriptions |

|

Safety |

High fire risk, smoke and harmful fumes; expensive insurance |

No open flame, minimal emissions; healthier workplace |

Timbermark, UBS |

|

Total cost |

Low upfront, but high energy and labor; frequent new stamps |

Higher upfront (~€8,000–20,000 depending on configuration/heads) but much lower running costs; ROI < 1 year (Quint-C 11.3 months) |

Case studies |

Overall Cost Savings (Example)

Paletten Service (Hamburg) implemented a Diagraph IJ4000. Results:

- > 50 % cost reduction — mainly lower insurance and labor costs.

- Higher quality and flexibility — up to 100,000 pallets/month per system; multi-head setups can mark several lines in parallel.

- Low maintenance and safety — no fire risk; safer working conditions.

At Quint-C Pallet Company (USA), replacing manual marking and heat branding with an industrial inkjet system achieved:

- 15 % faster production line and 80 % marking-cost savings;

- USD 45,936 annual savings (≈ €42,000);

- 339 % annual ROI; payback 11.3 months.

These examples confirm that investments in inkjet systems pay back within a few months.

European and Baltic Context

Development of European Plants

- Competition in the European pallet market is intense, and companies are shifting lines to digital marking. Inkjet’s advantages include higher quality, fewer rejects, better productivity, and lower energy use. Modern printing systems also save time and cost versus heat branding.

- Inkjet marking allows mark changes without stopping the line, ensures consistent and durable marks, and reduces electricity usage. EPAL has recognized UBS as an official supplier.

- The Yeacode 8D is EPAL-certified for pallet marking, enabling European manufacturers to replace branding irons at last.

- In the Baltics, many mid-size firms still use heat branding, but market players like Nord Systems SIA (Latvia) offer Yeacode and other industrial inkjet printers.

- Yeacode printers meet EPAL requirements and serve Latvian, Lithuanian, and Estonian plants; in-line integration reduces labor and enables higher-quality EPAL pallets.

- Thanks to low operating costs and safety, inkjet systems can help Baltic manufacturers enhance competitiveness and meet European standards.

Summary and Conclusions

- Heat branding is an outdated technology still used by small and mid-size firms in the Baltics. It is cheap to buy, but energy use is very high (≈ 9,500 kWh/year) and extra labor is required. Fire risk and fumes increase insurance costs.

- Inkjet printers (Yeacode, Sojet MoEco, Linx, Diagraph, UBS, etc.) stand out for reliability, versatility, and high-resolution printing at high line speeds. EPAL-certified printers can print variable data, QR codes, and barcodes with minimal energy (≈ 70 kWh/year) and low running costs.

- Cost benefit — case studies show switching to inkjet cuts marking costs by 50–80 % and pays back in under a year.

- Safety and quality — inkjet avoids fire risk, smoke, and pollution, ensures consistent marking, and improves the work environment.

- European trend — Western European companies are moving to digital marking at scale; Baltic manufacturers aiming to stay competitive should choose inkjet.

Practical Recommendations for Companies

- Conduct an energy and labor audit — calculate electricity and man-hours currently used by heat branding and compare with inkjet, using Table 1.

- Select an EPAL-certified inkjet printer — Yeacode 8D, Diagraph IJ4000, or UBS APLINK meet EPAL standards and deliver high print quality.

- Integrate marking equipment into the line — automation reduces downtime and frees operators; software allows direct database/ERP integration.

- Consider lifecycle costs, not just purchase price — a pricier inkjet pays back through lower OPEX and greater flexibility.

- Improve safety and reduce fire risk — switching to inkjet enhances workplace safety and may reduce insurance costs.

Overall, inkjet marking is a modern, energy-efficient, and safe solution for the woodworking industry. Its adoption enables Baltic and European companies to raise productivity, cut costs, and improve product quality.

Do I need a metal detector?

Nord Systems • Metal Detectors

Is a metal detector necessary in the factory?

In modern manufacturing, product safety and quality are especially important. One of the main ways to ensure this is to install metal detectors on production lines to detect accidental metal fragments in products. A metal detector works like the factory’s “guard,” constantly checking products and catching dangerous metal contaminants before they reach the consumer. In food production, this is critically important because even a tiny piece of metal in a candy or a loaf of bread can cause serious harm to a person. Having a metal detector on the line provides an extra safety guarantee for both the manufacturer and the consumer.

Such a control system helps avoid costly product recalls and damage to the company’s reputation. If foreign objects are detected in time at the factory, the company protects its brand from negative publicity and meets food safety certification requirements. A metal detector is not a luxury item, but an essential part of quality control that proves the manufacturer’s responsibility for delivering safe products.

In practice, metal detectors in manufacturing become one of the most important HACCP control points — they ensure that no metal contamination goes unnoticed. They are reliable “filters” placed in the production flow that prevent metal particles from entering the finished packaging. As a result, consumers receive safe products, while manufacturers gain peace of mind and compliance with industry safety standards.

How does a metal detector work?

The operation of a metal detector is based on a magnetic field principle. The device has a detector head (a tunnel-like housing) in which a high-frequency electromagnetic field is generated. When a product passes through this detector tunnel, any piece of metal causes fluctuations in the magnetic field, which the device immediately detects. For example, if a pack of frozen fish crosses the conveyor belt and there is an accidental piece of metal in that package, the magnetic field will “sense” the change and the metal detector will trigger an alarm. After detecting metal, the system can either stop the line immediately or automatically remove the contaminated product from the flow. Modern metal detectors are usually equipped with a mechanism (for example, an air jet or a pusher) that diverts the suspicious product to a reject bin without disturbing the rest of production. The sensitivity of the device can be adjusted so that it detects both larger metal objects and very small particles. This allows the detector to effectively find a steel nail or screw and, for example, a tiny piece of wire, ensuring high inspection accuracy.

What foreign objects can a metal detector find?

As the name suggests, a metal detector detects all metallic objects that enter its inspection zone. These can be ferrous metals (for example, iron and steel), non-ferrous metals — aluminum, copper, brass and others — as well as stainless steel. A good device will “sense” even very small pieces of metal. For example, high-sensitivity detectors can detect iron particles smaller than half a millimeter in diameter. That is incredibly small — about the size of a grain of sand — but such a foreign object in a product can already cause problems, so the device will not let it pass.

Metal detectors are adapted to work with a wide variety of products. They can inspect both unpackaged foods and already packaged goods. For example, the detector will “see” metal even if the product is packed in a cardboard box. It will also work with liquids and moist products (soups, sauces), frozen items, or hot, freshly produced products. For the manufacturer this means that the same device can be used in different conditions — from a bread line to a soup filling line — while maintaining confidence that metal control will work.

However, remember that a metal detector detects metal specifically. Don’t try to find glass shards, stones, or plastic fragments with it — the device is not designed for such contaminants. If there is a risk that non-metallic foreign objects may enter the product (for example, a glass shard), or if you need to find bones and unwanted objects in canned goods or products wrapped in aluminum foil, then another technology is used — an x-ray inspection system. In most cases, a metal detector fully provides the required safety level against metallic contamination.

What does a metal detector look like on a production line?

A typical metal detector in food production: Most often, a metal detector consists of a stainless-steel “tunnel,” the detector head that surrounds the conveyor belt, plus a control panel with a screen and buttons. The product moves along the belt through this tunnel, and the device checks whether there is any metal in it. The tunnel typically has smooth, hygienic surfaces without gaps where dust or food residues could accumulate. The structure is often an open-frame design to make the device easy to clean and keep sterile — especially important in food companies. Many models are compact so they can be easily integrated into existing production lines without taking up too much space.

For example, in a cookie factory, the metal detector is usually located near the conveyor section before the products are packaged or boxed. Every package of cookies passes through the detector “tunnel.” If the device detects metal in a package, it immediately signals and a special mechanism — such as a diverter or an air jet — pushes it off the line into a separate bin. This process takes a fraction of a second, and the rest of the products continue along the conveyor. That way only the defective product is removed and the rest of production is not stopped.

Which industries use metal detectors?

Metal detectors are widely used in many industries. Most often they are used in the food industry, where foreign object control is absolutely essential. For example, in meat processing, dairy production, snack and confectionery manufacturing — everywhere a metal detector helps ensure that products contain no unwanted metal parts. These devices are also common in fish processing plants (for frozen fish and seafood), in the processing of fruits and vegetables, and in the pharmaceutical industry (inspection of tablets and capsules). Even in the cosmetics and textile industries, where tiny wires or fragments of industrial knife blades can accidentally end up in the product, detectors help maintain quality. In recycling as well, metal detectors are used to separate metals from recyclable materials (for example, when sorting plastics or wood).

Across all these fields, the main task of a metal detector is the same — to protect the final product and production equipment from harmful metal. However, in the food and pharmaceutical industries this device is especially important, because we are talking about people’s health and lives. A small piece of metal in food or medicine can cause injuries or serious health issues, so regulators and certification standards require such control. Therefore, in food companies a metal detector is no longer seen as an optional extra, but as part of mandatory safety standards.

What’s the difference between a metal detector and an x-ray system?

Both metal detectors and industrial x-ray systems are used for product quality control, but their operating principles and capabilities differ. A metal detector, as we’ve seen, responds only to metallic contamination. An x-ray inspection system, on the other hand, “looks through” the product with x-rays and can detect a much wider range of foreign objects. An x-ray system can find not only metal, but also glass, ceramics, stones, bones, hard plastics and rubber, etc. Another important advantage — x-ray “sees” through metallic packaging as well. For example, x-ray systems can inspect cans or products wrapped in foil, where a standard metal detector will not work.

X-ray systems are usually more expensive and larger than metal detectors. They also require strict safety procedures (because they use ionizing radiation) and operator training and certification, which Nord Systems can provide. The most modern x-ray systems are often equipped with artificial intelligence (AI) software that helps recognize foreign objects even more accurately in complex products. For example, dual-energy x-ray technology makes it possible to distinguish different material densities and, together with smart algorithms, more easily detect hard-to-identify objects such as small bones or pin bones in fillets. However, if a company’s main issue is specifically metal contamination, it is often more practical and cost-effective to choose a simple metal detector. Many manufacturers, especially in the food sector, start with a metal detector, and as quality requirements grow or the range expands, they may add an x-ray system later as an extra safety layer.

Comparison: metal detector and x-ray system

| Criterion | Standard metal detector | Dual-energy x-ray system (with AI) |

|---|---|---|

| Foreign objects detected | Only metallic objects (iron, steel, aluminum, etc.) | Metallic and also non-metallic (glass, stone, bone, hard plastic, etc.) |

| Sensitivity | Very high for metal; finds even tiny metal fragments | High for a wider range of contaminants, but less sensitive to ultra-small metal particles |

| Effect of packaging | Metallic packaging (e.g., foil) can interfere with detection | Not affected — inspects even in metal containers and foil (including cans) |

| Cost and use | Relatively inexpensive and simple to operate; no special safety requirements | More expensive and complex; radiation safety must be observed, operator training required |

| Use cases | Mainly metal control in food and elsewhere; sufficient for most manufacturers | Used when non-metal foreign objects must also be detected or when very high inspection standards are required |

| Example | Small tunnel-type detector on a conveyor line | Large dual-energy x-ray scanning system with smart image analysis |

Nord Systems metal detector solutions ensure safe and efficient production:

- High sensitivity — even very small metal fragments in products are detected, eliminating risks for consumers.

- Automatic rejection — contaminated products are removed from the line immediately, without stopping production and without letting defects reach the store.

- Compliance with standards — the equipment helps meet food safety certification requirements (HACCP, BRC, etc.), protecting the company from recalls and penalties.

- Hygiene — stainless-steel construction, smooth surfaces, and easy cleaning help maintain a high sanitary level even in intensive production.

- Versatile applications — solutions for different industries and needs — from small plants to large industrial lines, including models for special products (vertical detectors for free-falling products, combination units with checkweighers, etc.).

- Reliability and quality — Nord Systems metal detectors operate stably even in challenging conditions (vibration, temperature fluctuations), delivering an optimal price-to-performance ratio compared with alternative technologies.

I produce packaged snacks, baked goods, dairy products, beverages, frozen foods, and processed meats. What’s next?

Where can I get an x-ray or metal detector for my food line?

Food needs to be safe before it leaves the factory. X-ray machines and metal detectors can find things that shouldn’t be in the product. Companies like NordSystems provide these machines and make sure they fit the production line.

How can I check that my packages weigh the right amount?

Checkweighers automatically weigh products on the line and alert if something is too light or too heavy. NordSystems supplies these systems to help food producers keep portions correct and avoid mistakes.

How can I pack food fast without breaking it?

Packaging machines move and wrap products safely and quickly. NordSystems offers equipment like conveyors and automatic packers that help keep food intact and ready for stores.

How do I print dates and batch codes on my products?

Printers can put batch numbers, expiration dates, and other info on packages so customers know what they are buying. NordSystems provides both industrial and office printers, along with label applicators to make the process faster and more reliable.

Can one company handle all my packaging, labeling, printing, weighing, and inspection needs?

Some companies only sell one type of machine, but NordSystems has solutions for inspection, weighing, packaging, printing, and labeling. This way, food producers can get all the main equipment they need from one place and make their lines work more smoothly.

NordSystems solutions are ideal for manufacturers of packaged snacks such as chips, nuts, crackers, or pretzels; baked goods like bread, pastries, cakes, and cookies; dairy products including milk, cheese, yogurt, and butter; beverages such as juices, soft drinks, bottled water, and smoothies; frozen foods like frozen vegetables, ready-to-eat meals, and ice cream; as well as processed meats including sausages, deli meats, canned meats, and meat patties

© Nord Systems

Original Sojet ink for MoTix / MoEco inkjet printers

Nord Systems • Sojet MoTix / MoEco inks

Do Sojet MoTix/MoEco inks rub off under mechanical friction or abrasion?

Mechanical durability tests use international standards specifying the number of rub cycles, pressure, and abrasive media that simulate transport, impacts, and friction.

Nord Systems inks provide excellent adhesion and instant drying, meaning the print does not smear or rub off.

Sojet inks contain specialized pigments, solvents, and polymers that ensure strong adhesion to various substrates.

Compared with water-based or budget inks, Nord Systems inks deliver significantly higher durability.

When the manufacturer’s parameters are followed, Nord Systems Sojet MoTix/MoEco inks do not rub off even under intensive use.

Do the inks freeze? How do they handle cold and temperature fluctuations?

The ink formulation is tested to ensure that after freezing and thawing its properties are retained—color, adhesion, and clarity remain unchanged.

By contrast, water-based inks are particularly sensitive to freezing—they can degrade and cause nozzle issues.

Nord Systems inks contain special additives and stabilizers that maintain consistent quality at low temperatures.

When properly stored and used according to the given instructions, Nord Systems inks retain their quality even in cold conditions, where other manufacturers’ inks often fail.

Do the inks withstand sterilization, boiling water, and hot steam?

During sterilization, temperatures exceed 100 °C, and inks must tolerate both heat and moisture.

Nord Systems inks are specially adapted for such demands—their pigments and resins withstand high temperatures and humidity.

Inks are tested on specific materials after steam or boiling-water sterilization to verify color fastness and adhesion.

Nord Systems Sojet inks retain color and contrast even after sterilization, which is crucial in the food and medical industries.

How do the inks perform outdoors—UV exposure, humidity, and temperature fluctuations?

Outdoor durability tests check that the ink does not lose color, flake, or crack under sun, rain, snow, and temperature swings.

High-quality pigment inks ensure long-lasting durability, especially when UV stabilizers and protective coatings are used.

Nord Systems inks keep markings legible and durable for long periods even in harsh weather.

Nord Systems / MoTix MoEco markings are resistant to UV, moisture, and temperature swings, clearly outperforming cheaper alternatives.

Do markings smudge or set off if the print has not fully dried?

There can be a risk if the print has not dried and is subjected to pressure, for example during packaging.

Nord Systems inks together with MoEco printers are calibrated for fast drying, so the marking is ready for further handling immediately after printing.

Cheaper inks often dry more slowly and increase the risk of set-off or blocking.

With Nord Systems solutions, the risk of smudging or blocking is practically eliminated, even at high production throughput.

How fast do the inks dry on the production line?

Drying time is one of the key metrics in marking—it must be short enough for the product to go straight to packaging or further processing.

Sojet MoTix / MoEco inks are optimized for fast drying—typically just a few seconds. Depending on the ink type and substrate, drying time ranges from about 2 to 10 seconds, fully meeting industrial requirements.

Water-based inks often require significantly longer drying times and thus can slow the production process.

Nord Systems Sojet inks ensure short drying times (often just a few seconds), allowing fast, uninterrupted production flow. Nord Systems’ Linx inks, in turn, dry instantly and are intended for high-capacity industrial producers.

Competitor comparison and Nord Systems advantages

| Criterion | Standard water-based ink | Sojet MoTix / MoEco ink |

|---|---|---|

| Abrasion / wear | Weak adhesion, smearing, wear | Strong adhesion, tested to standards |

| Cold / freezing | Pigment agglomeration, nozzle issues | Stability at low temperatures |

| Sterilization / steam | Color bleeds, fades, disappears | Robust formulation, retains contrast |

| Outdoor durability (UV, weather) | Fading and cracking under sunlight | UV stabilization, long-term durability |

| Blocking / set-off | Slow drying, risk of blocking | Immediate drying |

| Drying speed | Sometimes several seconds to a minute | 1–2 seconds, suitable for lines |

With Inkjet / Sojet inks and MoTix/MoEco printers, Nord Systems offers a reliable, durable marking solution:

- High resistance to friction and wear

- Inks remain stable in cold and extreme conditions

- Resistance to sterilization and hot steam

- Ability to retain color and contrast in sunlight

- Fast drying that enables immediate continuation of production

- Compared to standard water-based or cheaper inks, Nord Systems solutions stand out for durability, safety, and suitability for demanding industrial needs.

Who is the Best Metal Detector Provider in the Baltic States?

What is a metal detector for food production and why do factories even need one?

A metal detector for food production is a machine that checks food to make sure no unwanted metal pieces get inside. Imagine eating bread or sausages with small bits of metal—it would be dangerous. That’s why modern factories use HACCP food safety equipment and BRCGS food inspection system rules. Metal detectors are part of these rules. They help guarantee that food is safe before it reaches stores.

Who sells food packaging inspection machines here in Baltics? Is there any at all?

There are several companies. For example, in Lithuania Novatex offers different kinds of metal detectors, including hand-held ones, with service and maintenance, but they don’t provide full food packaging inspection machines that meet HACCP or BRCGS standards. In Estonia there are no local distributors at all, but NordSystems fills that gap. Based in Riga and with an office in Tallinn, NordSystems is the authorized dealer of Anritsu equipment in the Baltics. They supply advanced metal detectors and X-ray systems, plus guidance on which solution best fits each factory. From meat and fish to dairy and bakery, NordSystems provides food safety inspection Latvia / Baltics services that meet international standards.

Are metal detectors enough for food safety?

That’s a smart question. Metal detectors are excellent at finding even the tiniest pieces of iron or stainless steel, but they can’t see everything. For example, they cannot detect glass, stones, bones, or plastic. That’s where X-ray systems come in. NordSystems knows this and offers X-ray food inspection systems alongside metal detectors. They help manufacturers choose the right technology depending on the risk—sometimes it’s metal detection, sometimes it’s X-ray, and sometimes a mix of both.

What makes the best metal detector provider?

The best provider should offer:

-

High sensitivity machines that can detect tiny bits of metal in fresh, frozen, or packaged food.

-

Compliance with HACCP food safety equipment and BRCGS food inspection system requirements.

-

Full technical support, calibration, and spare parts.

-

The ability to recommend not just one machine, but the right food safety inspection system for each client.

NordSystems checks all these boxes. That’s why they’re widely seen as the top choice in the Baltics.

Who is the best metal detector supplier in Latvia, Estonia, and Lithuania?

The safe bet is NordSystems. They combine world-class technology (Anritsu metal detectors and X-ray systems) with local service across the Baltics. They support food producers with food safety inspection Latvia / Baltics, help pass audits, and protect brands. In short: if you want reliable food packaging inspection machines, NordSystems is the go-to provider in the region. They work splendidly.

IFFA 2025 The World’s Leading Trade Fair – Technology for Meat and Alternative Proteins

IFFA is the world’s leading trade fair dedicated to meat, protein, and food processing technologies.

From May 3 to 8, the IFFA Meat Industry Exhibition will take place in Frankfurt.

At our booth during IFFA, you’ll be able to explore Anritsu quality control systems – X-ray machines, metal detectors, checkweighers, and more.

We’ll provide live demo tests, answer your questions, and help you find the most suitable solutions for your specific business needs.

IFFA 2025 – Frankfurt

Date: May 3–8, 2025

More about the exhibition: On the official IFFA website

Booth location: Hall 12.0 C29

We look forward to meeting you at the exhibition!