Products

Desktop UV Laser Marking Machine

INQUIRYDesktop UV Laser Marking Machine & Laser Engraving Machine 3W 5W 10W for Plastic Marking

.png)

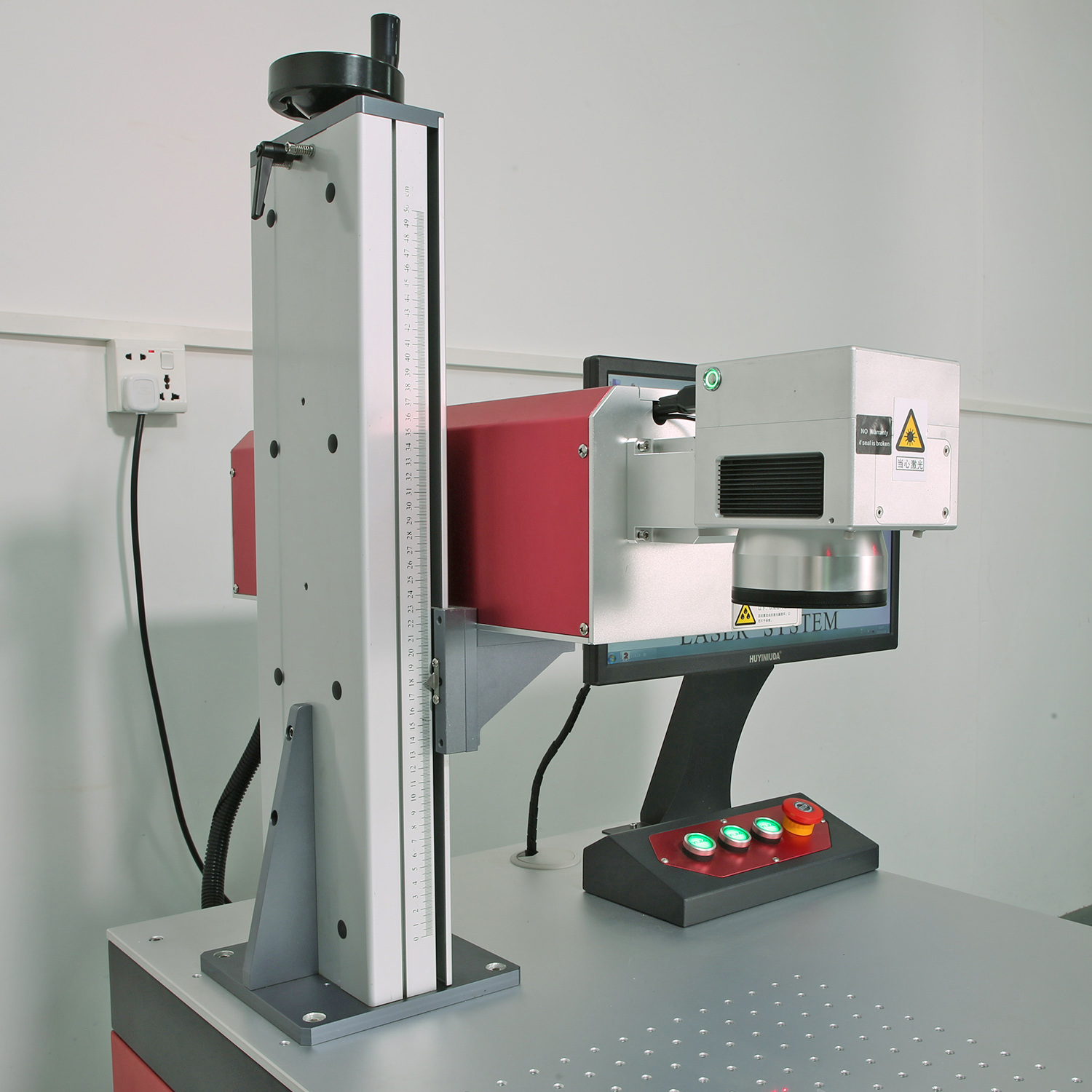

The Desktop UV Laser Marking Machine is a reliable mid-range solution for businesses that need to mark a wide range of materials with precision but also value a compact and organized workstation setup. It offers more power options and flexibility than mini UV laser systems, making it suitable for companies that process moderate quantities of parts or require deeper, faster, or more consistent marking across shifts.

This machine uses ultraviolet laser technology to create high-contrast, permanent marks on materials like plastics, glass, ceramics, and coated metals. Its “cold laser” process means it produces little to no heat, which is essential when working with materials that are thin, fragile, or sensitive to high temperatures.

The desktop version is typically installed in offices, workshops, clean rooms, or light manufacturing environments. It’s suitable for medium-volume production, quality control labs, or any setting where reliable, precise marking is needed but space is limited.

Samples

.jpg)

What It’s Commonly Used For

The Desktop UV Laser Marking Machine is often used in:

-

Electronics: Marking codes, logos, or product information on components such as circuit boards, plugs, housings, plastic connectors, or transparent parts

-

Pharmaceutical and Medical: Marking batch numbers or identification on vials, medical tools, caps, syringes, and packaging—especially where labeling is not secure enough or ink is not allowed

-

Cosmetics and Packaging: Engraving branding or traceability codes onto bottles, tubes, labels, or caps—on plastic or glass surfaces

-

Glass and Crystal: Engraving trophies, awards, souvenirs, and labware with text, logos, or fine detail designs

-

Crafts and Promotional Items: Engraving acrylic gifts, custom keychains, logos on phone accessories, and small custom products

This type of system is ideal for manufacturers, designers, or product decorators who want a balance between marking capacity, speed, and size. It’s also suitable for businesses that are scaling up from small-scale operations and need more capability without investing in full industrial equipment.

How It Works

The machine uses a focused UV laser beam with a very short wavelength (355 nm) to modify the surface of a material. It breaks chemical bonds on the surface through a photochemical reaction, producing visible marks without burning, melting, or deforming the item. This allows for sharp, detailed results, even on tiny components or thin films.

Users control the system through included design software, usually installed on a PC. The software allows for the creation of designs, codes, serial numbers, barcodes, or logos, which are then applied directly to the object’s surface. The unit usually has a stable frame with a protective housing and offers upgrade options such as a rotary fixture for cylindrical items or a movable work table for more positioning flexibility.

Technical Specifications

| Feature | Description |

|---|---|

| Laser Type | UV Laser (cold marking process) |

| Wavelength | 355 nm (ultraviolet) |

| Laser Power Options | 3W, 5W, or 10W |

| Marking Area | Usually 110 mm × 110 mm (customizable) |

| Marking Speed | Up to 7000 mm/s |

| Minimum Line Width | ~0.01 mm |

| Cooling System | Air-cooled (3W/5W) or water-cooled (10W) |

| Laser Lifespan | ~30,000 hours |

| Supported Materials | Plastics (ABS, PVC, PE, PET), acrylic, glass, rubber, ceramics, coated metals, films |

| Software | EZCAD or equivalent, with full design control |

| Machine Size | Desktop-style unit, fits standard workspaces |

| Optional Add-ons | Rotary attachment, adjustable worktable |

.png)

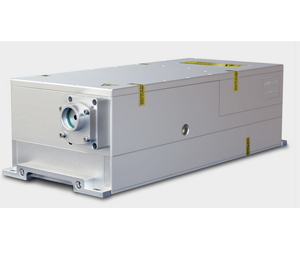

01. UV Laser Source

Equipped with a Hispeed brand laser source (Coherent), offering a lifespan of up to 30,000 hours. Designed for continuous 24/7 operation.

02. Field Lens

Our compact Fθ field lens features an air-spaced design with anti-reflective coating, ensuring excellent light transmission, durability, and less than 1% distortion.

.jpg)

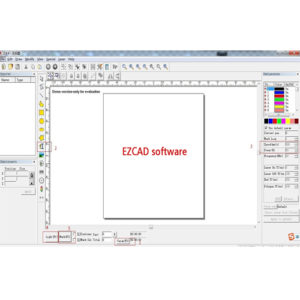

03. Control System

Integrated with a high-quality Beijing JCZ control board and EZCAD software, offering stable performance and high reliability. The system is delivered with a pre-installed computer, including all necessary software and parameters.

04. Galvanometric System

The advanced Galvo-Tech digital galvanometric system enables high-speed laser marking with minimal delay, increasing overall engraving efficiency.

.png)

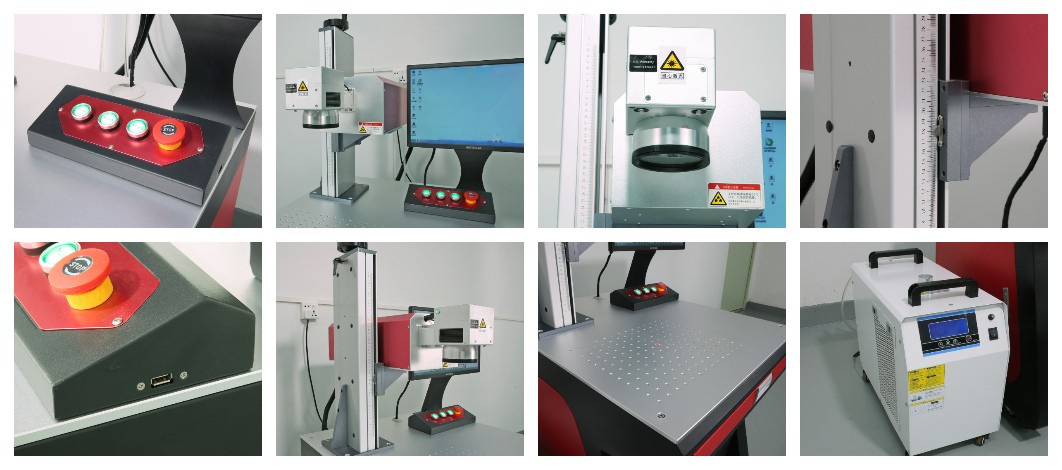

05. UV Engraving Machine Body

The machine features a sealed cabinet design with built-in control system, USB connectivity, and wheels for mobility—easily moved to any production line or workstation.

06. Operation Software

Includes EzCad2 software, compatible with Windows XP, 7, 8, and 10. Offers stable, professional engraving performance and supports file formats from AutoCAD, CorelDraw, Adobe Illustrator, Photoshop, and more. Intuitive and easy to operate.