Products

Go beyond contaminant detection

INQUIRYOur x-ray inspection system can detect low-contrast contaminants such as plastic and bone.

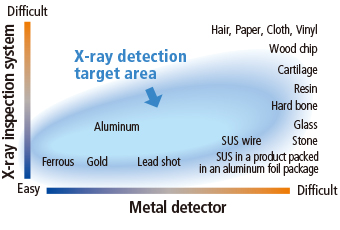

The attributes of x-ray inspection systems and metal detectors for contaminant inspection.

X-ray systems can detect stone, plastic, and bone ass well as metal contaminants. Metal detectors can detect the entire range of metals such as ferrous, non-ferrous, aluminum, etc. Since the principle of detecting contaminants differs between x-ray systems and metal detectors, the type of likely contaminants needs to be considered in selecting the appropriate inspection system.

Is x-ray system better than metal detector?

X-ray system detects plastic, rubber, etc. as well as metal fragments. It seems that x-ray system excels in detection performance when comparing the type of detectable contaminants. However, metal detector detects some of foreign objects that cannot be detected by x-ray system.

X-ray systems can detect stone, plastic, and bone ass well as metal contaminants. Metal detectors can detect the entire range of metals such as ferrous, non-ferrous, aluminum, etc. Since the principle of detecting contaminants differs between x-ray systems and metal detectors, the type of likely contaminants needs to be considered in selecting the appropriate inspection system.

Is x-ray system better than metal detector?

X-ray system detects plastic, rubber, etc. as well as metal fragments. It seems that x-ray system excels in detection performance when comparing the type of detectable contaminants. However, metal detector detects some of foreign objects that cannot be detected by x-ray system.

The difficulty of detecting contaminants

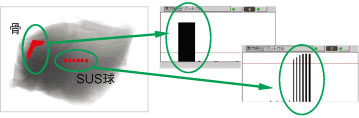

Best-in-class inspection capability - 0.2 mm diameter metal

The Anritsu UltraHD technology installed in our machines can detect even the most minute contaminants - 0.2 mm diameter ferrous, non-ferrous and stainless steel spheres at production line speeds. Tuning the algorithm to match the new high-sensitivity sensor easily detects low-contrast contaminants such as bone and plastics.

*Using the h-series with our in-house test pieces.

Anritsu's ability to detect contaminants with high accuracy, sensitivity and repeatability is unmatched in the industry.

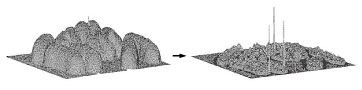

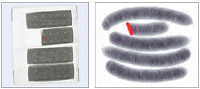

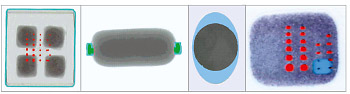

The unprocessed x-ray image (below) includes noise due to the shape and characteristics of the inspected item. Anritsu signal-processing technology and image-processing algorithms accurately capture contaminant signals.

*Using the h-series with our in-house test pieces.

Anritsu's ability to detect contaminants with high accuracy, sensitivity and repeatability is unmatched in the industry.

The unprocessed x-ray image (below) includes noise due to the shape and characteristics of the inspected item. Anritsu signal-processing technology and image-processing algorithms accurately capture contaminant signals.

Signal processing advancements allow detection of smaller contaminants.

Signal processing (filtering) of x-ray images two or more times enhances detection of contaminants signals, realizing detection of diverse contaminants ranging from soft contaminants such as bone to metal contaminants.

Signal processing (filtering) of x-ray images two or more times enhances detection of contaminants signals, realizing detection of diverse contaminants ranging from soft contaminants such as bone to metal contaminants.

Shape Detection

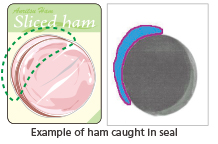

| Package Check Packages of sliced ham, etc., are checked to ensure none of the contents is caught in sealed parts.  |

Void Check Inspects voids and air bubbles entrapped in retort food, cheese, or butter for maintaining freshness.  |

Missing Product Detection

Checks product count in package, mass and fill level for missing products.

Checks product count in package, mass and fill level for missing products.

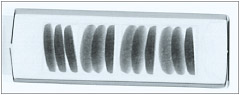

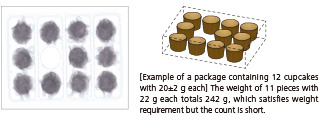

[Count detection] Inspects the number of pieces per pack of vertically packed biscuits or cookies. |

[Virtual weight detection] Shortages in the number of items in a package can be found when the amount is displayed as number of contained pieces and detecting such shortages based on mass is difficult, because each piece has variable mass. |

| Shape Detection The shape, area and mass are analyzed from x-ray images to find irregularities including breaks and chips. Missing fillings can also be spotted.  |

Mask Functions Detection sensitivity is improved by masking according to product characteristics such as forms and shapes.  |

A 15-inch wide-screen display for comfortable operability

Projection monitor

The x-ray image is displayed graphically by limit to increase comprehension. Simple operations change the limits to enhance detection sensitivity.

Software features

* Simultaneous inspection for all types and sizes of contaminants

including wire, glass, stone, and bone.

* Optimized settings per application, 70+ unique algorithms.

* Dynamic filters greatly enhance detection with reduction of

possible false rejects.

* Full auto-learn process - all x-ray settings are learned at the

touch of a button.

* Password protected - once set the system can be locked out

from changes by production staff.

* Allows multiple reject criteria including contaminant, virtual

weight, count, missing and more.

* Full reject log and image capture capability with time/day stamps

for all rejected products.

* Built-in multi-lane system capability - 1 to 4 lanes.

* Stable, repeatable performance

* Full auditing capability through Anritsu's Operation Check for

HACCP compliance

Simple maintenance

Tool free belt removalNo tools are required for removing/attaching the conveyor belts and rollers including the front cover and x-ray leakage prevention curtain.

Easy-to-clean design

Anritsu x-ray inspection systems (except the 74-f series) are certified to IP66 dust-proof/waterproof. The system's angled surfaces prevent water from accumulating after system cleaning. The sanitary design line-up of two models with IP69K is also available.

Simple information management

X-ray images and inspection logs can be saved to the USB memory for HACCP compliance. All Anritsu systems can be connected, via Ethernet, to QuiCCA. QuiCCA provides line status information, centralized reporting and data storage.

Anritsu safety mechanism

- Emergency stop switch

Cuts power to x-ray and drive circuits, stops the conveyor and

x-ray radiation. - X-ray ON/OFF key

Turning the key to OFF stops x-ray radiation completely. -

X-ray shield cover open/close sensorOpening the cover stops X-ray radiation.

- X-ray shield cover

Opened/Closed using x-ray Irradiation ON/OFF Key. Opening the

cover stops x-ray radiation dueto the x-ray Shield Cover

Open/Close Sensor. - X-ray irradiation display

The lamp is lit during x-ray radiation. - Leakage prevention curtain

Prevents x-ray leakage. For unpackaged or bulk products, the

standard lead impregnated curtains are replaced with SUS plates

and covers - preventing direct food contact with the curtains. - Hand insertion sensor

Interrupting the sensor for a certain period of time stops x-ray

radiation.

Safety management

X-ray Inspection System has been designed to fully satisfy the safe operation. However, to ensure even higher safety, use the safety procedures outlined below.

- Periodic measurement and recording of x-ray leakage data

- Management of operator working hours

- Additional safety measures

Covers may need to be mounted on upstream and downstream conveyors instead of the shield curtains, depending on the shape, weight,

and package of products. - No disassembly or modification

NEVER modify or disassemble the main unit, covers, x-ray leakage prevention curtains, safety covers, safety interlocks, etc., otherwise

the x-ray leak-proof design may no longer be functional.

Safety of inspected products

WHO concluded in 1980 that the “irradiation of any food commodity up to an overall average dose of 10 kGy presents no

toxicological hazard and introduces no special nutritional or microbiological problems.”

The maximum dose of x-ray irradiation to the products to be inspected by our x-ray inspection systems is 0.002 Gy, which is

much lower than the value described above. Even if a product stops inside, the x-ray dose is always kept to 0.1 Gy or less.