Products

Shrink Wrap Machines

INQUIRYProtective film wrapping for products

Shrink wrap machines are used to wrap products or product groups in shrink film. The film is heated and tightly conforms to the package.

This makes the packaging more stable, protects the product from dirt and damage caused by friction, and simplifies bundling and packing into transport boxes.

These machines are often used as an end-of-line packaging system in food, pharmaceutical, and consumer goods production.

What is shrink wrap packaging?

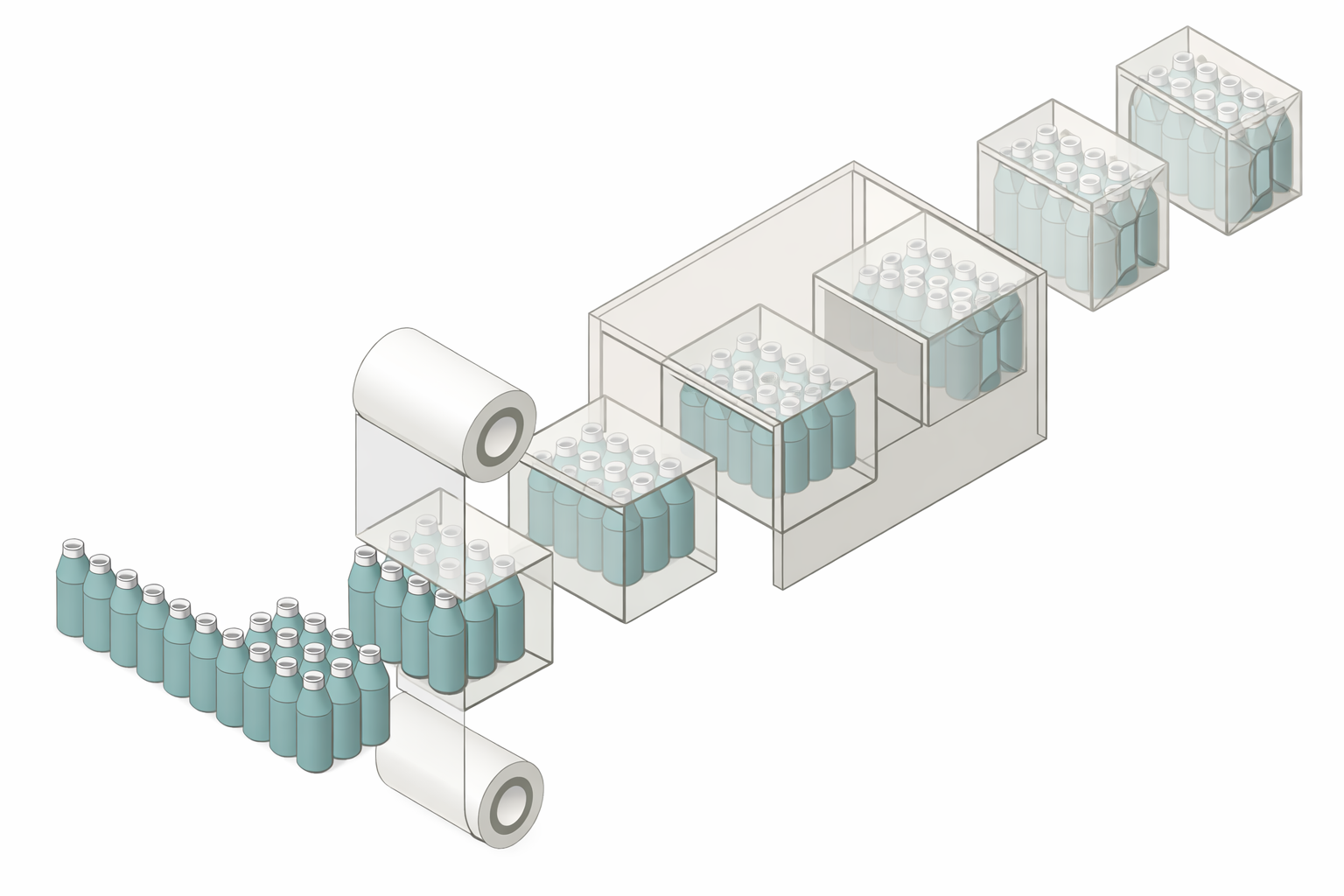

Shrink wrap packaging is a process where a product or product group is placed into shrink film. The package is then conveyed through a heat tunnel. Under heat, the film shrinks evenly and conforms to the product. The result is transparent and secure packaging. Any attempt to open it leaves visible signs.

How does a shrink wrapping machine work?

A typical shrink wrapping system consists of several stages:

- Film application – the film is wrapped around or placed over the product

- Sealing – the film is sealed around the product

- Shrink process – the product passes through a heat tunnel and the film shrinks around it

- Cooling and discharge – the package is ready for further processing

Machines can operate continuously and can be easily integrated into conveyor lines.

Why use shrink wrap packaging?

Shrink wrap packaging offers several advantages:

- Protection against dust, moisture, and damage

- Stability during transportation

- Prevents unauthorized package opening

- Product visibility through transparent film

- Bundling of multiple products

Shrink wrapping is typically used as an additional packaging layer together with cardboard packaging.

Typical applications

Shrink wrapping machines are used for:

- Bundling food products

- Bottles, jars, and cans

- Packaging frozen food

- Consumer goods multipacks

- Pharmaceutical secondary packaging

Suitable for both individual products and group packaging.

Using multiple machines at the end of the line

Strapping machine systems are often used together with shrink wrap packaging solutions:

- Shrink film — for product bundling or surface protection

- Strapping — for load stability

A typical end-of-line flow may include:

- Cartoning or packing products into boxes

- Box sealing

- Shrink film wrapping

- Strapping

- Palletizing

Nord Systems develops solutions that allow manufacturers to choose the right load securing method based on product type, weight, and transport method.