Products

Carton Erectors

INQUIRYCarton Erectors and Carton Sealers

Carton erectors (box folding machines), Carton sealers and load securing (strapping) — an end-of-line packaging stage for stable, safe and consistent shipment preparation.

Carton Erectors (Box Folding Machines)

Automatic and semi-automatic forming of cardboard boxes from flat blanks

Carton erectors, also called box folding or box preparation machines, automatically convert flat corrugated cardboard blanks into three-dimensional boxes. These machines open the blank, fold the bottom flaps and seal them, creating a stable box ready for filling for subsequent packaging processes.

Carton erectors are usually installed at the beginning of the end-of-line packaging system. They are widely used in food production, logistics, and in the packaging of pharmaceuticals, dietary supplements, cosmetics and medical goods.

What does a carton erector do?

A carton erector automates the most labor-intensive stage of secondary packaging.

The process:

- Takes a flat corrugated cardboard blank from the magazine.

- Opens the blank and gives it a three-dimensional rectangular shape.

- Folds the bottom flaps.

- Seals the bottom using adhesive tape or hot-melt glue.

- Discharges the formed box onto the conveyor.

.jpg)

Why use a carton erector?

Manual box folding is slow, inconsistent and physically tiring. Automated carton forming improves both productivity and workplace safety.

Main benefits:

Modern carton erectors can handle different box sizes, and provide fast tool-less format changeovers.

Carton erectors – applications across industries

Carton erectors are widely used for:

- Shipping cases for food, cosmetics, consumer goods, etc.

- Secondary packaging in retail.

- Frozen food logistics cases.

- Transport of beverages and dairy products

- Packaging snacks and confectionery products.

The machines are designed to work with corrugated cardboard cases, which are commonly used in food supply chains, pharmaceutical distribution, cosmetics and consumer goods manufacturing, as well as logistics — anywhere transport packaging is required.

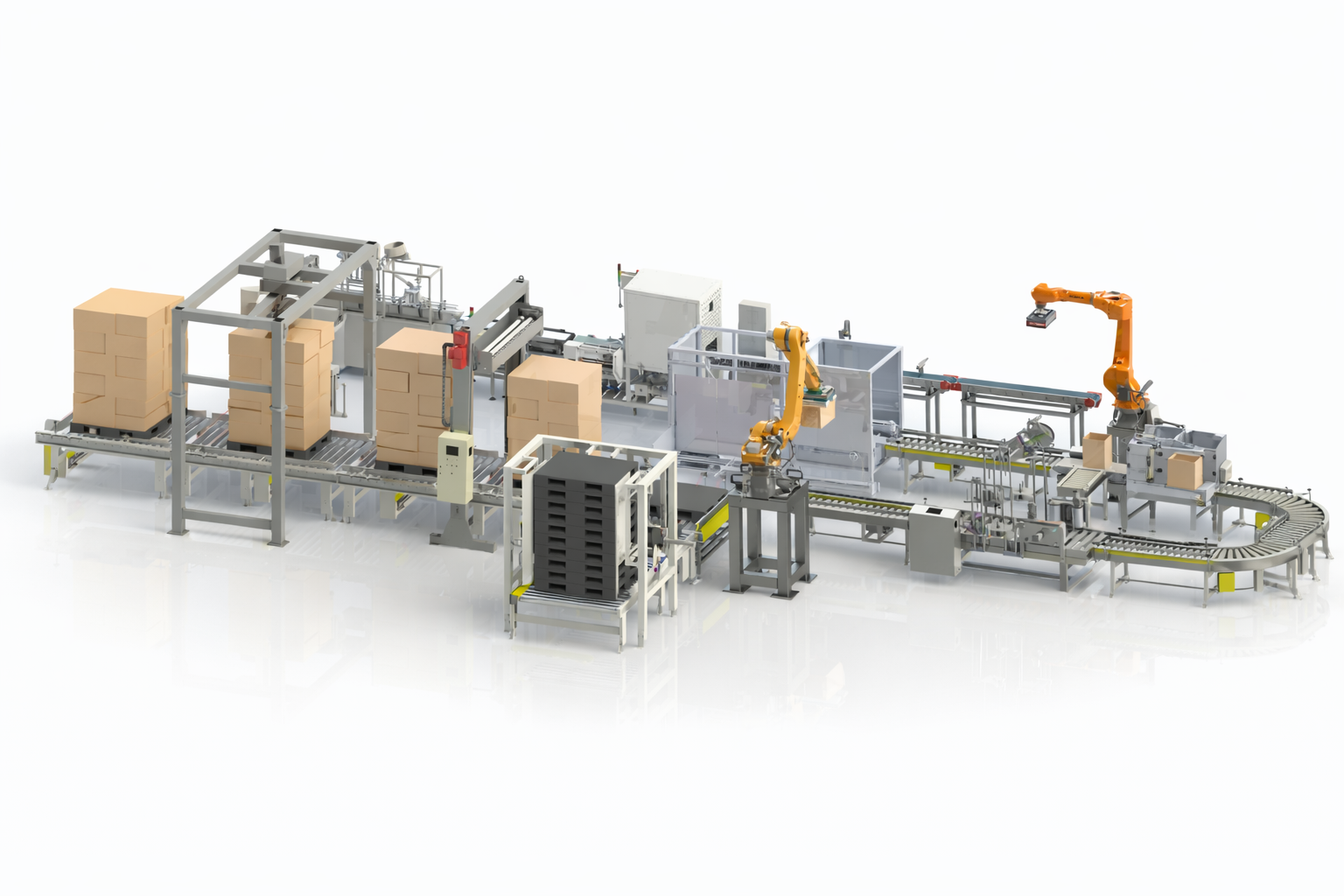

Integration in packaging lines

Carton erectors are typically combined with:

- Cartoning machines.

- Robotic "pick-and-place" systems. (robot arms)

- Carton packers.

- Carton sealers.

- Palletizing systems.

Together these machines create a continuous, automated line flow.

Carton sealers and packaging securing

(Automatic closing and sealing of filled cases)

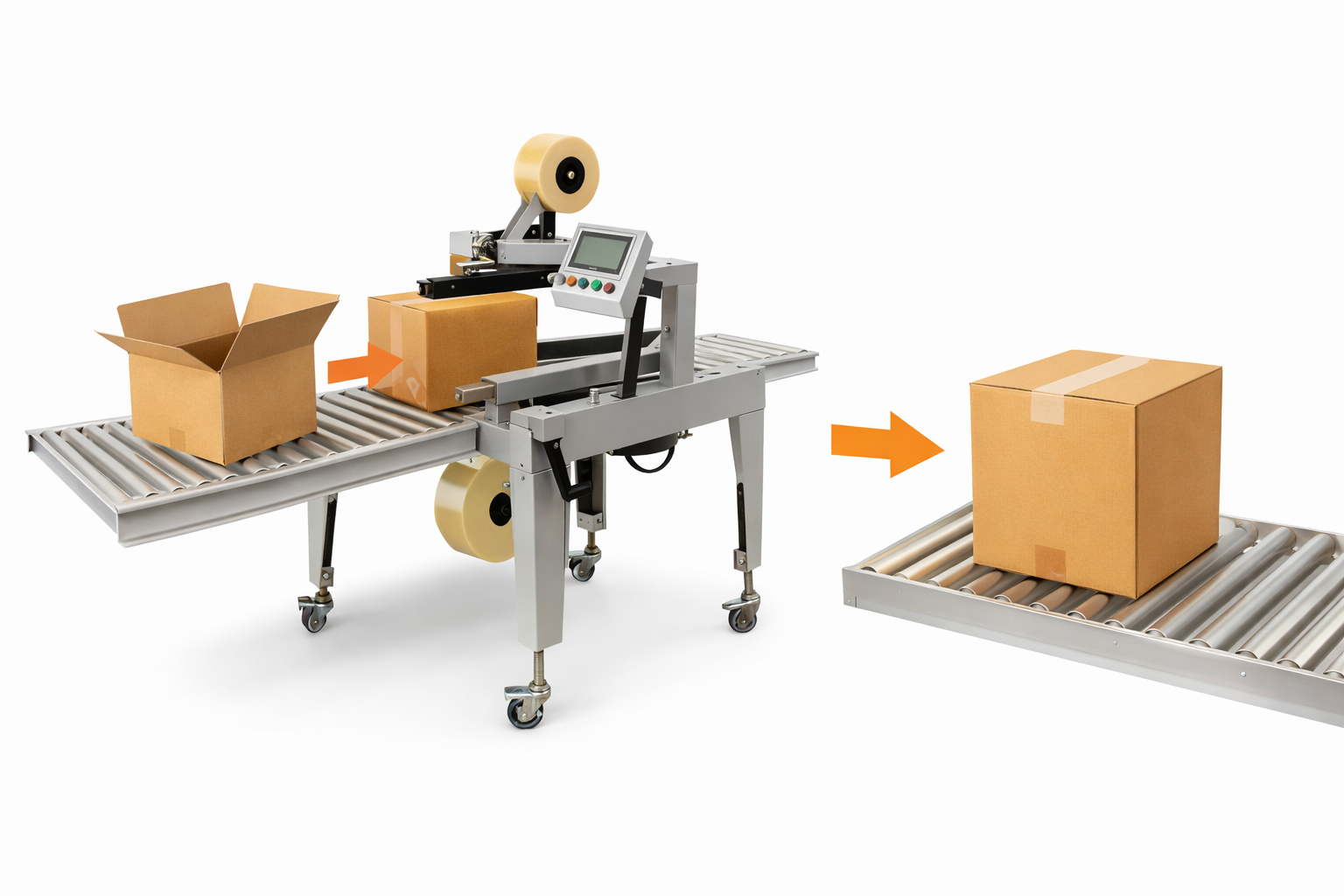

Carton sealers automatically close and seal filled cases, ensuring secure packaging before transportation or palletizing. These machines are typically installed after the packing stage.

What does a carton sealer do?

When cases are filled with product, the sealer:

- Folds the top flaps.

- Applies adhesive tape or glue.

- Discharges the sealed cases back onto the conveyor.

It guarantees closure and protects products during handling and transport.

Key benefits of automated carton sealing

Carton sealers can be configured for:

- Top sealing only.

- Bottom sealing only.

- Simultaneous top and bottom sealing.

Carton sealing in the food industry

In food production, carton sealers are used for:

- Shipping cases with packaged food.

- Transport cases for frozen products.

- Beverage and dairy logistics.

- Large-volume food service (HoReCa) packaging.

Automated sealing reduces human contact and helps comply with hygiene standards. In pharmaceutical and medical goods supply chains, automated sealing helps ensure packaging protection against unauthorized opening (tamper-evidence), transport safety and compliance with regulations, especially when combined with serialization, marking or inspection systems.

Strapping machines

Strapping machines provide an additional layer of load security by wrapping plastic or textile straps around sealed cases or packaged bundles.

They are typically used when:

- Cases are heavy.

- The load requires additional stability.

- Products are stacked in piles before palletizing.

Strapping can be performed after carton sealing to secure the packaging before dispatch.

Fully automated line

A typical automated system includes:

- A carton erector.

- Packing products into cases (cartoning).

- A carton sealer.

- Additional strapping.

- Palletizing.

NordSystems develops solutions that allow food producers to gradually expand automation, while ensuring service, safety and efficiency.